Key Pesticide Intermediate: 2-Chloro-5-Methylpyridine 2-Amino-5-methylpyridine is a key intermediate in the production of high-efficiency, low-toxicity, and low-residue nicotine-based pesticides, such as insecticides imidacloprid and acetamipri...

Share

Key Pesticide Intermediate: 2-Chloro-5-Methylpyridine

2-Amino-5-methylpyridine is a key intermediate in the production of high-efficiency, low-toxicity, and low-residue nicotine-based pesticides, such as insecticides imidacloprid and acetamiprid. It offers numerous advantages, including systemic action, broad spectrum, low toxicity, minimal dosage, safety, high efficiency, long-lasting effects, and strong resistance to pests, making it a preferred choice for agricultural insecticides. The global annual sales for these products amount to billions of dollars. 2-Chloro-5-methylpyridine, also known as 2-Chloro-5-methylpyridine (CMP), has a molecular weight of 127.57 and CAS number 18368-64-4. It is a colorless, clear liquid with a distinctive odor, insoluble in water but easily soluble in acid to form salts. It has a melting point of 16-18°C and a boiling point of 53°C (at 4 mmHg).

Preparation of 2-Chloro-5-Methylpyridine

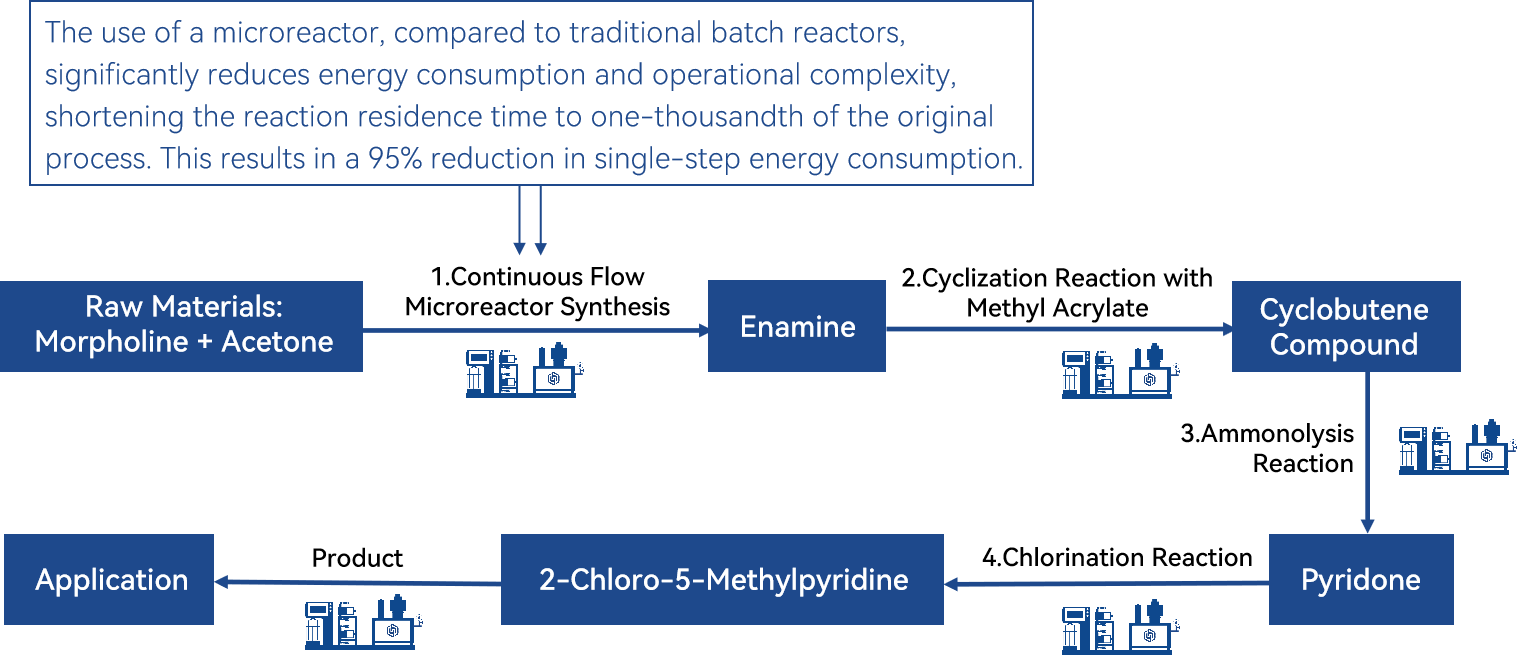

Preparation of “Monochloro (2-Chloro-5-Methylpyridine)” via the Morpholine-Propanal Method Using a Continuous Flow Microreactor

Role of YHCHEM Continuous Flow Microreactor

The role of the continuous flow microreactor in this process is primarily reflected in the following aspects:

01.Enhancing Reaction Efficiency:The microreactor offers a larger surface area, which facilitates efficient heat and mass transfer, thereby boosting reaction efficiency.

02.Reducing Energy Consumption:Thanks to its unique structural design, the microreactor allows for more effective control of reaction conditions such as temperature and pressure, resulting in lower energy consumption.

03.Enhancing Safety:The continuous flow reaction mode in the microreactor reduces the potential for energy accumulation, making the entire system safer and more stable.

04.Minimizing Waste Generation:Optimized reaction conditions in the microreactor lead to fewer by-products, reducing costs associated with waste treatment and disposal, and positively contributing to environmental protection.

05.Improving Automation:The use of microreactors enhances automation in production, reducing operational complexity and labor intensity, making the production process safer and more reliable.

Through these steps and the role of YHCHEM’s continuous flow microreactor, the morpholine-propanal method for producing "monochloro" not only improves production efficiency and safety but also significantly reduces environmental risks and production costs, achieving green and sustainable development.