The Ammonia synthesis reactor is mechanically driven by four hydrogen gas turbines, accelerates the reactor to 1,100 revolutions per minute and thereby also Ammonia in its flow pressurized.

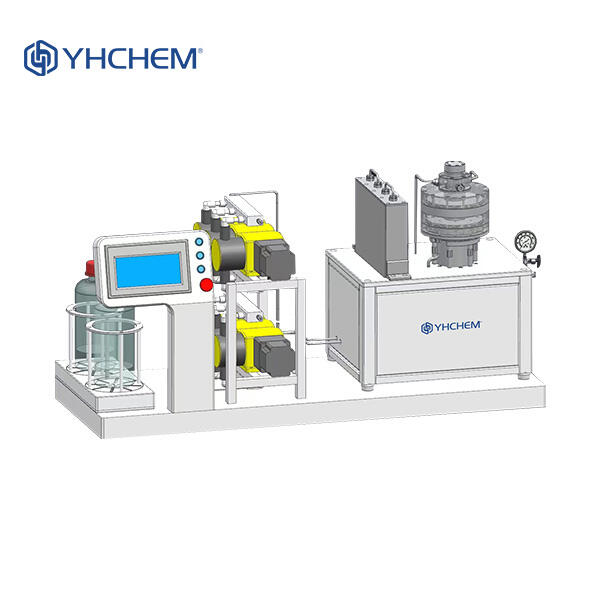

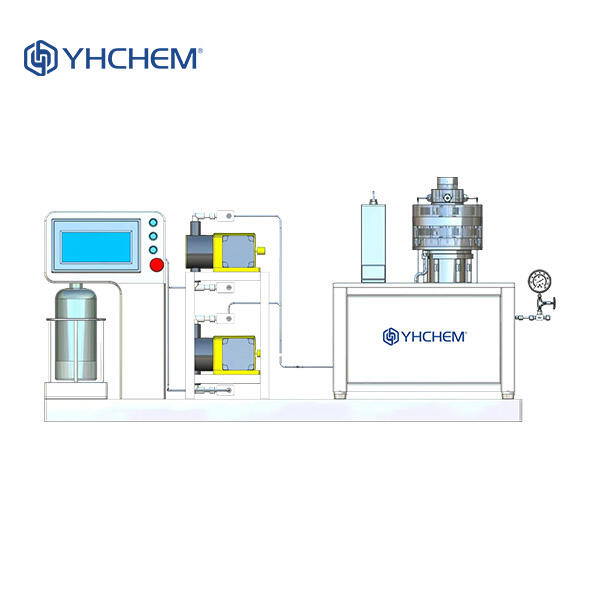

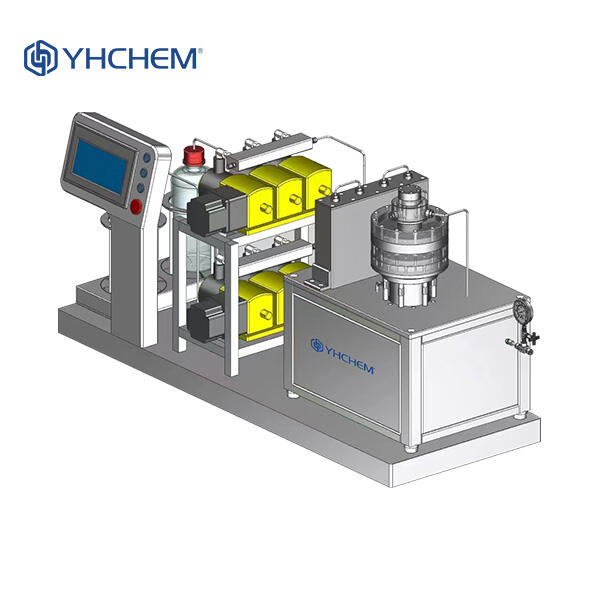

Need a reliable and hassle free way to produce chemicals? The breakthrough ammonia synthesis reactor from YHCHEM. The modern technology has many benefits due to its better improvement in the safety features, high-quality of output solutions and applicable across various industries. In this incredibly informative product review, I am going to reveal and explain more detail by glass reactor so you can deploy your organization in a better manner.

Ammonia synthesis reactors have several advantages over conventional chemical production processes. Its footprint is safety-first - working at low pressures and temperatures to mitigate risks of accidents/exploration. This cutting-edge method will use fewer flammable materials, creating a safer workplace.

Innovation - The modernistic use of instruments for fugitive production

State of the art technology is applied in ammonia synthesis reactor, which would improve fuel efficiency regarding ammonia. These are based on new reactor types that have been custom developed with catalysts - formulated to produce better yields in addition to higher purity. Furthermore the reactor is equipped with advanced monitoring systems that make it possible to perform real-time data analysis, which in turn allows us to verify around-the-clock none of parameters are compromised but also enables responses virtually instantaneously if anything abnormal has occurred.

These are Safety Guidelines as we want secure use.

Though the ammonia synthesis reactor is equipped with enough safety elements, an appropriate handling in congruence to the standards of security using and agreement are elementary. Tip: Always wear proper personal protective equipment (PPE) such as gloves, goggles and respiratory masks when handling all chemicals. Make sure the professionals can handle, only then need to run the reactor in commissioning or maintenance even for normal situations. A well-ventilated environment is required to contain a YHCHEM reactor, so the toxic gases will not gather.

The jacketed glass reactor by YHCHEM is only 3 steps that you have to optimize across the board.

Turn reactor on and use advanced control technologies for validation

Collect and store the produced ammonia outcome by category.

Dependable customer support is the cornerstone to any business, big or small. Ammonia Synthesis Reformer Services for Maximum Productivity and Longevity. Our team of experts are available 24/7 to provide prompt top quality service ranging from basic chemical glass reactor maintenance and up-taking.

We provide a range of products include glassware, ammonia synthesis reactor control, distillation reaction instruments. Our product line is specifically designed to meet the needs different industries. With a variety of service supply stations, we offer customers scientific all-in-one products services that provide prompt technical support as well after-sales services throughout their use.

We provided products a myriad of well-known businesses over 100 countries we have gained a wide amount appreciation and trust. We're dedicated enhancing our ammonia synthesis reactor and products based on customer feedback.

We possess leading technological innovations R and D strength globally, actively introducing international advanced technologies continually conducting independently driven technological innovations and innovations. have established joint labs in collaboration with research institutions such as the Shanghai Chemical Industry Research Institute East China University of Science and Technology. These laboratories are dedicated offering customers most ammonia synthesis reactor products and solutions.

We have stable financial position and sustainable development capability a listed ammonia synthesis reactor. We will continue to adhere market demand-oriented principles which drive continual product improvement technological advancement to generate new opportunities and value for investors, customers, and employees.

The biggest benefit of Ammonia synthesis reactor is generation consistent top quality high class production when it pertains to ammonia. Regardless of application, agrochemical or industrial the state-of-the-art technology of our reactor ensures that its outcome and purity are regular. Designed to withstand the most unfavorable of circumstances and produce kind of results which makes it a legacy any wolf will be proud to inherit.

Use Case: The Utility Varies Across Different Industries

Ammonia synthesis reactor has the feature of extensive application with a variety of-an enterprises used. Something as important as ammonia in fertilizer cannot be produced without water, in agriculture; It is also applied to produce a variety of industrial chemicals including plastics, and the reactor. In a similar way, the ammonia synthesis reactor that is used to store renewable electricity can also be employed in fuel cells (for automotive and other applications).

The double jacket glass reactor is a marvel of chemical production. Ideal for businesses aiming to increase productivity through it's state of the art technology, safety focus and high output performance Backed with wide support solutions and use-cases makes this product a great purchase across all industry types. We have the other half of this new, cutting-edge next-generation product ready to go for you today.