Best 5 Distillation Column Designs for Efficient Separation Processes

The Finest 5 Distillation Column Designs for Efficient Splitting up Processes

Have you been looking for a Distillation column design is both efficient and safe for your splitting up treatments? After that take a check, out these designs by YHCHEM. We will provide you with consequently of the 5 Distillation column most designs useful in the marketplace, and simply how they have the ability to gain your splitting up procedures.

1. Simple Distillation Design

Simple Distillation is an essential way used by dividing fluids with varying factors that are steaming. This heating activity is an uncomplicated mix of liquids until one vaporizes, after that gathering and condensing the vapor going back to a fluid. This duration is duplicated until the preferred splitting up is accomplished. Its benefits consist of simpleness of use, cost, and suitability for dividing fluids with considerable steaming point differences. Also, specific equipment can raise effectiveness, and automation choices exist to reduce manual labor. Safety precautions such as preventing fires throughout heating and ensuring proper air flow crucial. Simple Distillation discovers applications in several markets, from separating petroleum to dividing chemicals that are easily breakable. To use it, one simply fills the Distillation flask using the mix, connects the Distillation condenser and column, heats up the flask, and gathers the condensed vapor. With reduced upkeep and accessible equipment Simple Distillation is great for small-scale splitting up treatments, offering top quality splitting up outcomes.

2. Fractional Distillation Design

Fractional Distillation Design stands for an advancement over simple distillation column, particularly customized for dividing liquids with better steaming factors. This method utilizes columns that are fractionating by condensers, where each line consistently vaporizes and condenses the mix as it progresses inside out. Its benefits consist of greater effectiveness, cost-effectiveness, in addition to the power to divide fluids with smaller sized steaming point. Development in the use is involved by this technique of greater degree products to boost effectiveness along with easy for automation to reduce manual labor. Safety factors to consider consist of ensuring proper air flow to hold the accumulation of harmful gases and implementing manages to hold substance unstable build-up. Fractional Distillation is well-suited for separating chemicals that are complex and is especially effective for separating oil items. The fractionating column and condenser heats up the flask to start steaming, and repeats the treatment until the required splitting up is accomplished to use this process, one fills the Distillation flask because of the fluid mix connects. With readily equipment that can be found reasonably low-to-zero upkeep requirements, in addition to the power to produce top quality splitting up outcomes, fractional Distillation would certainly help small to medium-scale splitting up applications.

3. Steam Distillation Design

Heavy vapor Distillation Design is normally utilized for drawing out necessary oils specific grow. This process involves putting the grow material in a vapor distillation unit with steaming sprinkle, triggering heavy vapor to increase and feel the material, bring away beads of essential oil. The heavy vapor will be condensed and split, leaving behind the important oil. Its benefits would certainly be the capacity to extract oils that are all-natural, are necessary suitability for home use, and applicability for small-scale manufacturing. Advanced equipment can improve removal effectiveness, while precautions such as safety equipment air proper flow required to avoid accidents and breathing of dangerous vapors. Perfect for drawing out essential oils from plants, the process involves filling the heavy vapor Distillation flask with grow material and sprinkle, heating the mix, and gathering the heavy vapor and condensed vapor in a getting flask. With readily equipment that can be found low-to maintenance-zero, and quality affected by the beginning material, heavy vapor Distillation serves small-scale manufacturing of essential oils.

4. Short-Path Distillation Design

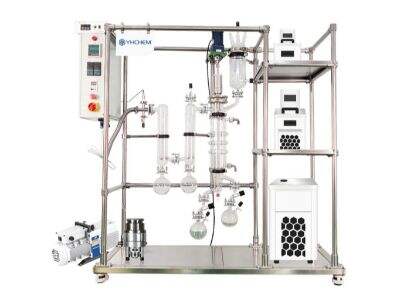

Short-path Distillation is an incredibly efficient and effective method accomplishing high pureness the splitting up of compounds, commonly used to divide your lives all-natural oils and various other complex mixtures. The technique involves vaporizing the mixtures under high vacuum, enabling the vapors to travel merely a brief range the Distillation columns before condensing. This brief travel range reduces the opportunity of contamination, thus ensuring high purity. The benefits of short-path Distillation consist of high pureness splitting up and high effectiveness which makes it fit to dividing mixtures that are complex. Developments in the area, like the use of products with superior thermal conductivity, can further improve effectiveness. However, the technique requires concentration on safety, as high cleanser quantities require unique safety equipment plus the potential presence of eruptive compounds requires stringent safety. The flask to steam the mix under high cleanser and gather the condensed vapor the receiving flask to use short-path Distillation, one must fill the Distillation flask because of the mix, connect the short-path Distillation unit and condenser, temperature level. The equipment may need specific maintenance it has an enhanced application cost, nonetheless it supplies the finest of splitting up, rendering it perfect for large-scale chemical separations.

5. Azeotropic Distillation Design

Azeotropic Distillation is a specific form of Distillation utilized when 2 fluids, whose steaming factors are shut, form an azeotrope—a mix of fluids that boils at a continuous temperature level. This Distillation method works by including another fluid for your mix, producing a ternary azeotrope allows the 2 initial liquids become separated. The benefits of azeotropic Distillation consist of effective splitting up of fluids with azeotropes and suitability for separating temperature-sensitive compounds. Developments in specific equipment can further increase effectiveness. However, the use is essential because of the means of safety equipment to avoid injury. Azeotropic Distillation is especially useful for dividing temperature-sensitive substances and the ones that form azeotropes. To use this technique, one must fill the Distillation flask while using the mix of fluids, include the Third liquid produce a ternary azeotrope, heat the flask to steam the mix, and gather the condensed vapor into the obtaining flask. The device for azeotropic Distillation is very easily available and needs fairly zero-maintenance, while still creating splitting up is top quality. This system works for dividing substances that form azeotropes.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN