YHCHEM continuous flow microreactor uses a unique internal structure to form rapid turbulent flow of internal materials, which can improve fluid mixing, enhance mass transfer and heat transfer, and is suitable for multi-phase reactions and reactions under high-risk or harsh conditions. According to different scenarios Providing one-stop customized services aims to shorten reaction time, reduce resource waste, improve product quality and purity, eliminate safety risks, reduce environmental pollution, and achieve seamless scale-up from laboratory to industrial production. Yuanhuai continuous flow microreactor can perform reactions under a variety of different reactor types and conditions. The modular system components are flexible and easy to use and are suitable for sulfonation, format, hydrogenation, nitration, oxidation, esterification, and diazotization. Such reactions are widely used in fine chemicals, pharmaceutical intermediates, nanomaterials, polymer materials and other industries.

Six Major Advantages Supporting the Chemical Industry

● Applicable Processes

Nitration, oxidation, chlorination, fluorination, and 18 other hazardous chemical processes under key supervision.

● Application Fields

The application fields are broad, covering pharmaceuticals, agrochemicals, dyes, fragrances, electronic chemicals, and more.

● Material Options

A variety of materials are available, including 316L stainless steel, silicon carbide (SiC), Hastelloy, C4 stainless steel, PTFE, and more.

● Optional Functions

Solid feeding, weighing and metering, pH detection, and online analysis.

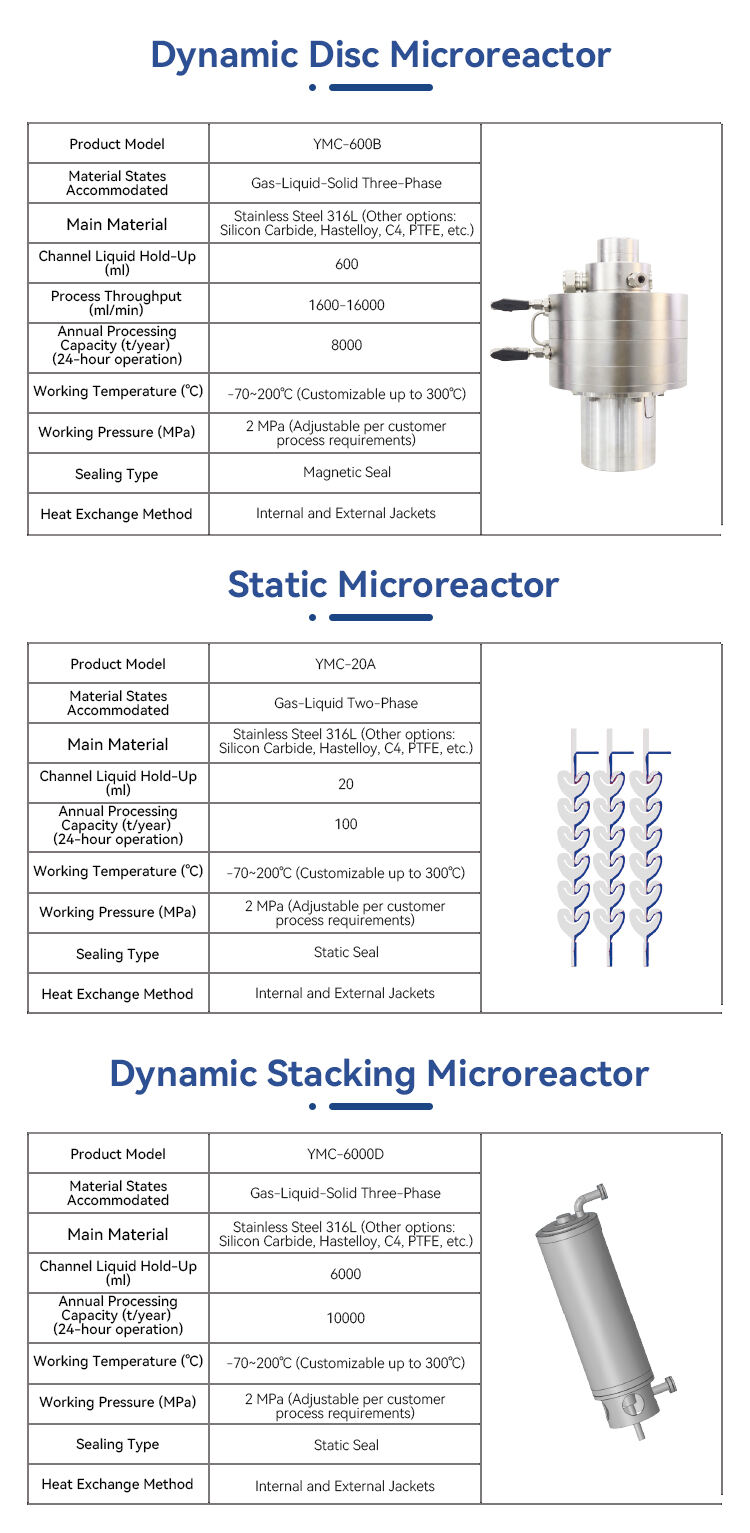

● Various Models

Dynamic disc, static microchannel, tubular reactor, and fixed-bed reactor are available for selection.

● Customized Processes

Comprehensive process solutions for solid-liquid reactions, liquid-gas reactions, extraction, distillation, drying, and other systems.

Technical Advantages

● High Mass and Heat Transfer Efficiency ● Precise Process Control

● Reduced Side Reactions ● Minimal Scale-Up Effects

● Short Production Cycle ● Small Reaction Volume

● Maximum pressure up to 40 MPa ● Operating temperature up to 300°C

● Ranges from 10 to 1000 microns ● Liquid hold-up capacity of 10 to 6000 mL

● Superior Mixing Performance ● Convenient Online Monitoring

● Modular Design ● Automation

● Excellent Corrosion Resistance, Suitable for high-pH compounds and hydrofluoric acid.

● Stainless steel, silicon carbide, Hastelloy, and others.

User Value

● Low comprehensive investment ● Low energy consumption

● High product yield ● Small footprint

● High product purity ● Low operating cost

● High product selectivity ● Minimal catalyst usage, long service life

● High production efficiency ● Minimal waste

● Small liquid hold-up, intrinsically safe ● Rapid scale-up

Application Fields

● Pharmaceuticals and Chemical Intermediates

● Pesticides

● New Materials

● New Energy

● Military Industry

● Fine Chemicals

● Dyes

● Fragrances and Flavors

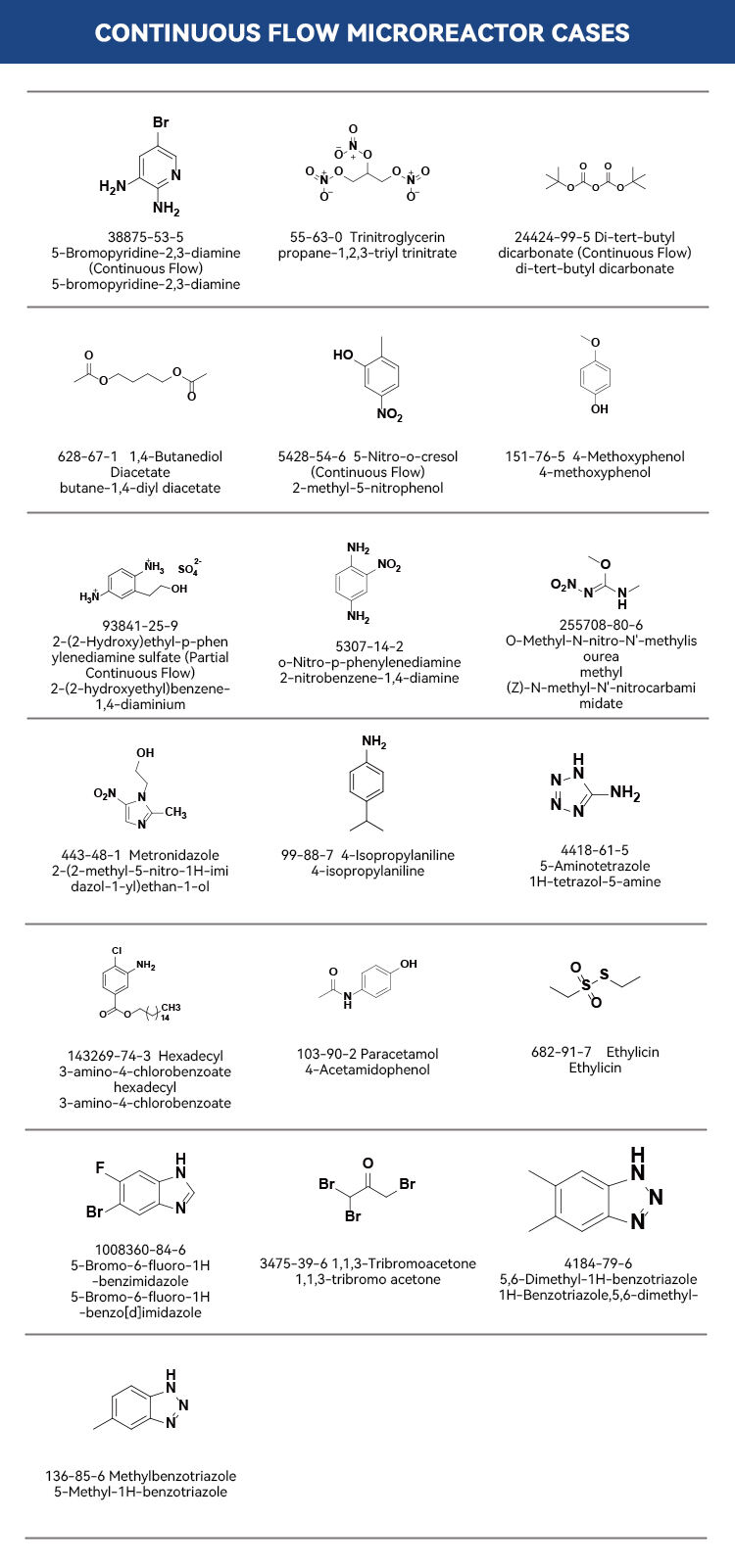

● Nitration, Sulfonation, Diazotization, Oxidation, Fluorination, Hydrogenation, Chlorination, Halogenation, Bromination, Polymerization, Cyclization, Isomerization, Esterification, Grignard Reaction, Amination, Alkylation, Hydroxylation, Acid-Base Neutralization