With the advancement of technology, more and more natural substances are being utilized in the cosmetics and fragrance industries. However, the extraction and purification of these substances often present significant technical challenges. Yuanhuai T...

Share

With the advancement of technology, more and more natural substances are being utilized in the cosmetics and fragrance industries. However, the extraction and purification of these substances often present significant technical challenges. Yuanhuai Technology is dedicated to providing high-quality solutions for its customers. This particular solution focuses on the purification of a specific plant oil. Starting with crude materials obtained at the front end, the process completes the purification of the plant oil and the recycling of solvents (n-hexane, methanol, ethanol).

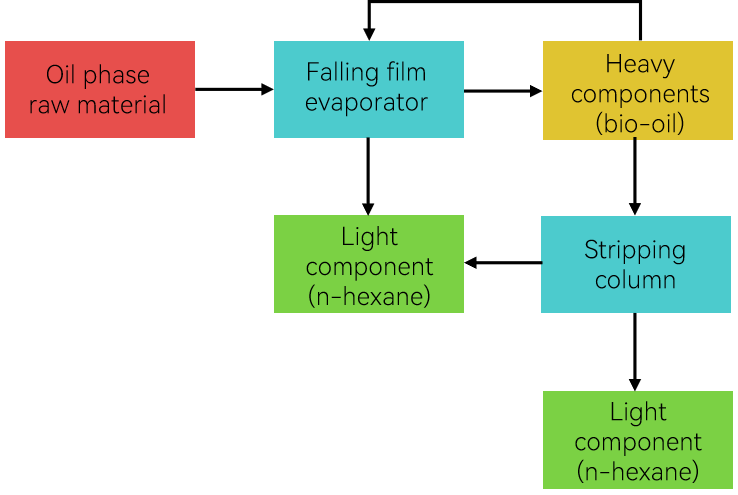

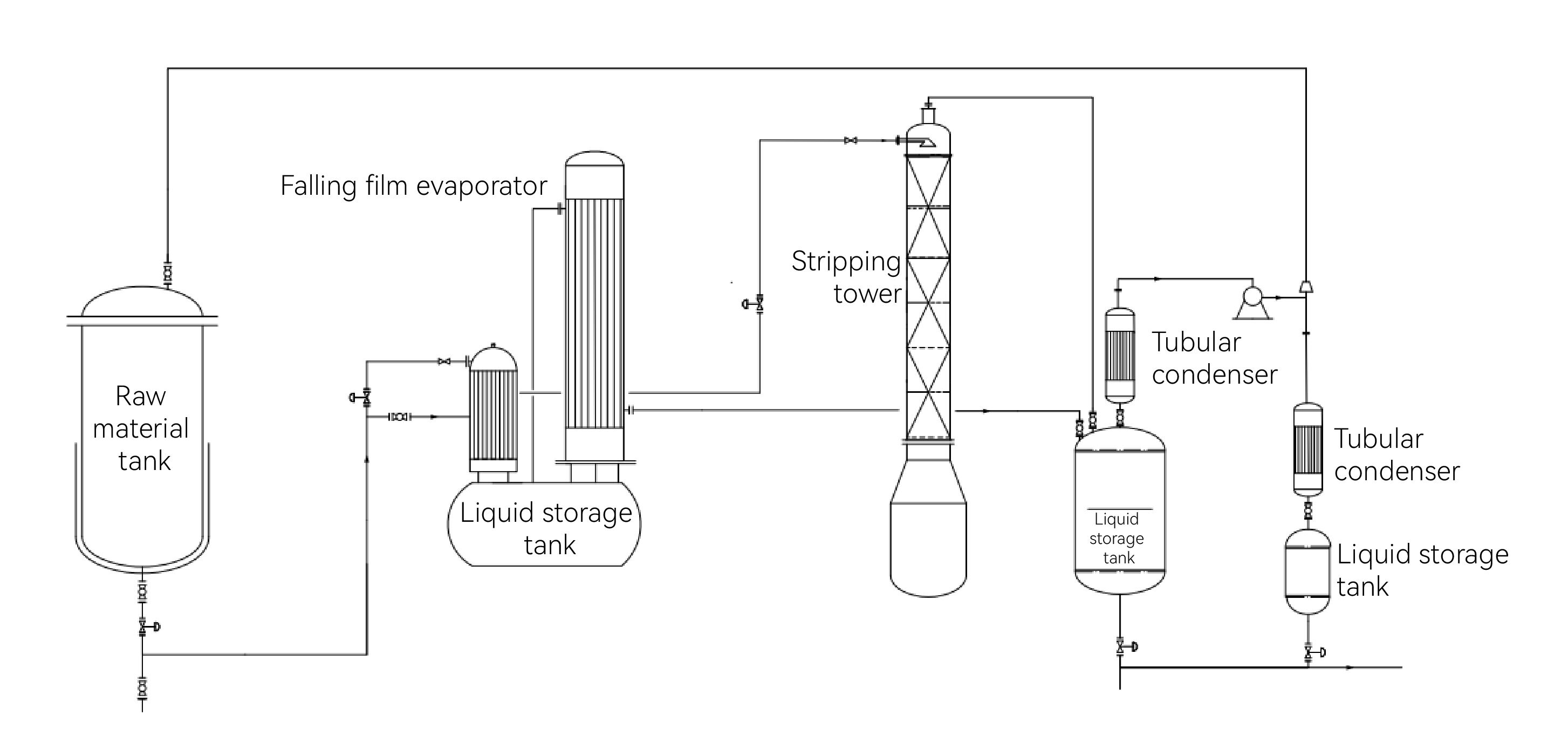

For the crude oil phase materials, light components are first removed using a falling film evaporator (or alternatively a rising film evaporator, thin film evaporator, or molecular distillation equipment). The heavy components continuously circulate in the falling film evaporator until they meet the required standards. The plant oil is then further purified through a stripping column, achieving the goal of plant oil purification, with the final product containing solvent residues of less than 10 ppm.

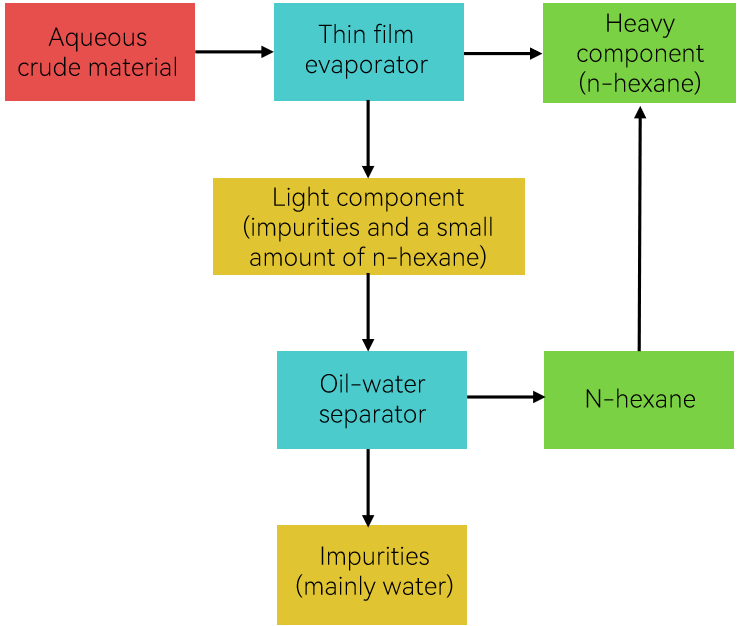

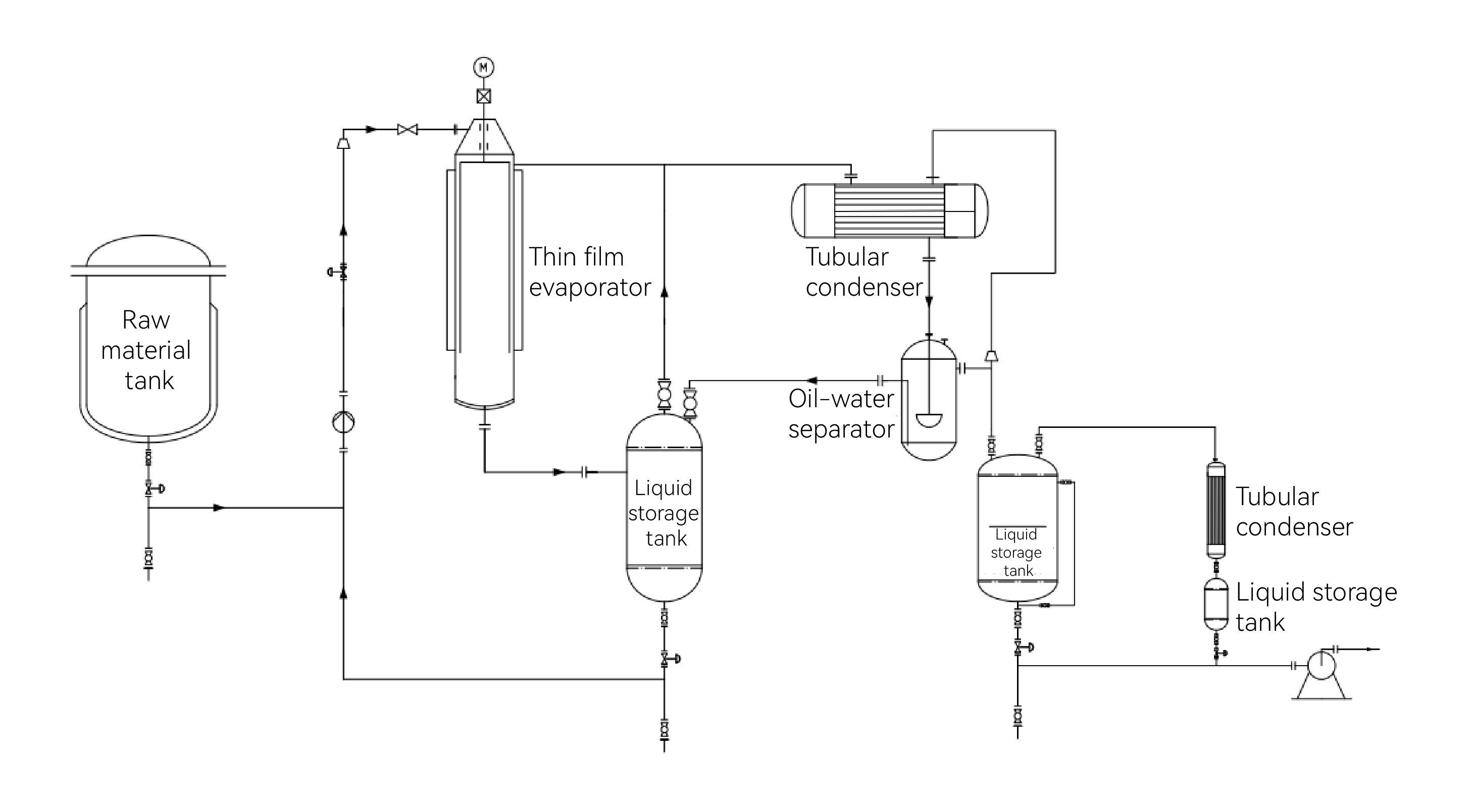

For the aqueous crude material, a thin film evaporator is used to separate the solvent from other impurities. After the light components are removed, an oil-water separator is used for further separation, and part of the solvent is recovered. This process enables solvent recycling, thus reducing costs and improving efficiency for the customer.