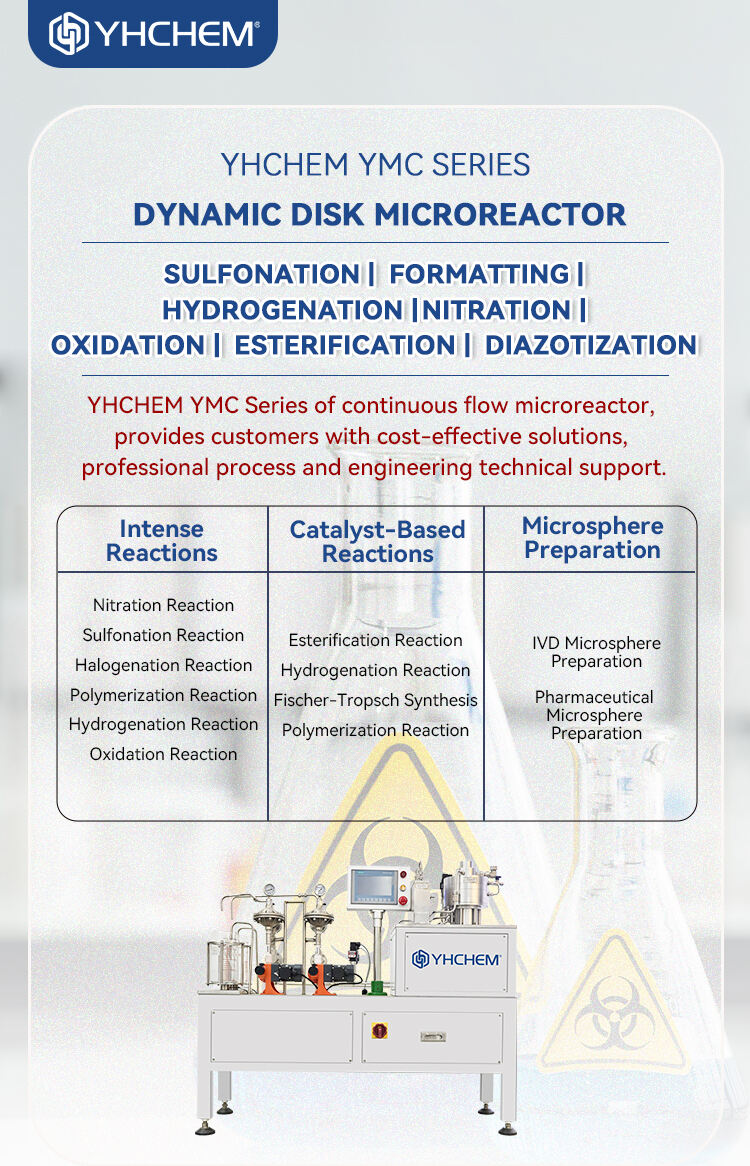

YHCHEM dynamic disk microreactor uses a unique internal structure to form rapid turbulent flow of internal materials, which can improve fluid mixing, enhance mass transfer and heat transfer, and is suitable for multi-phase reactions and reactions under high-risk or harsh conditions. According to different scenarios Providing one-stop customized services aims to shorten reaction time, reduce resource waste, improve product quality and purity, eliminate safety risks, reduce environmental pollution, and achieve seamless scale-up from laboratory to industrial production.

Wide range of applications

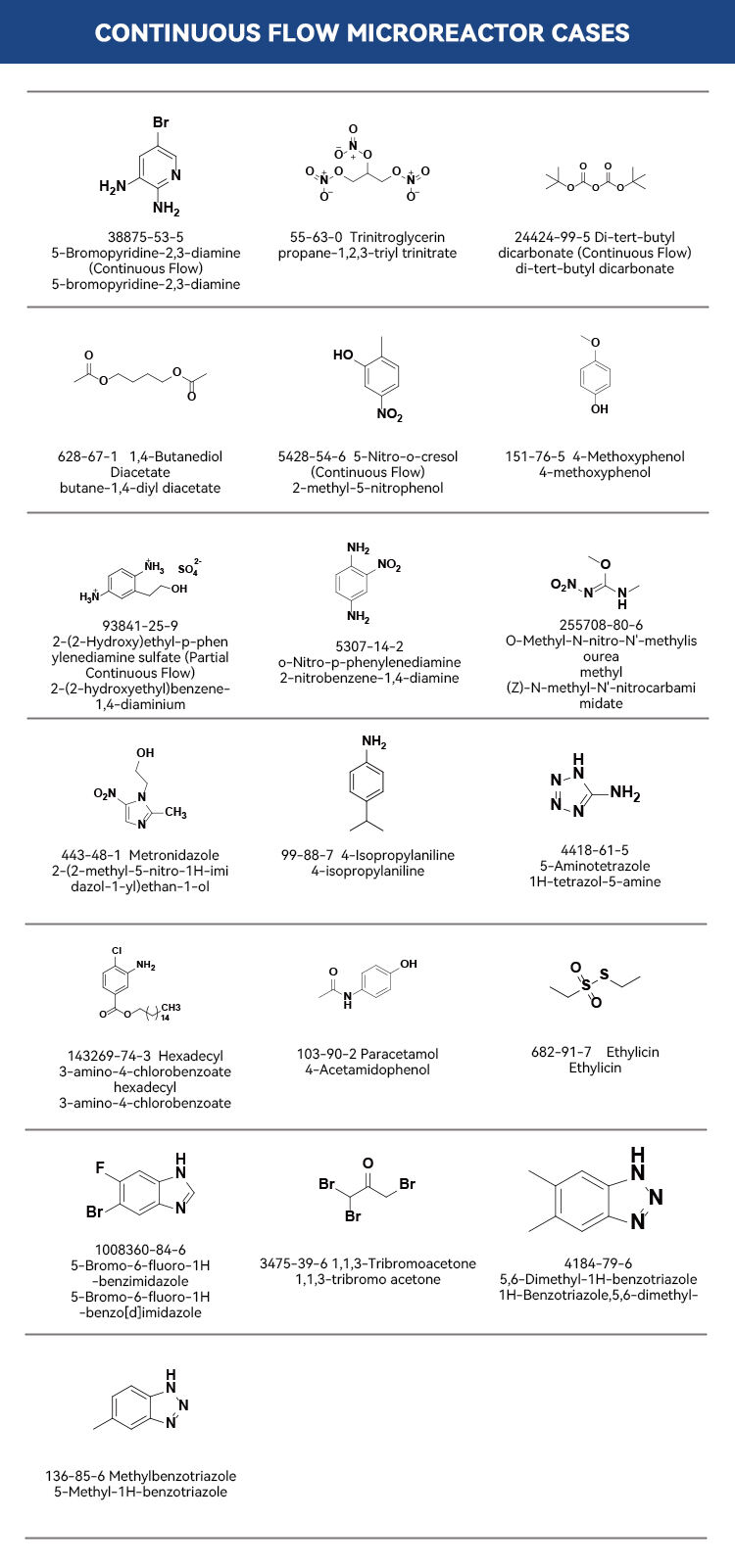

Pharmaceutical intermediates, drug synthesis, fine chemicals, pesticide chemistry, special chemicals, daily necessities industry, nanomaterials, pharmaceutical preparations, polymer modification, etc.

Common reactions including nitration, sulphonation, diazotisation, oxidation, peroxidation, hydrogenation, chlorination, fluorination, halogenation, polymerisation, cyclisation, isomerisation, esterification, amination, alkylation, hydroxylation, acid-base neutralisation, etc. can be carried out using the microreactor.

Process characteristics

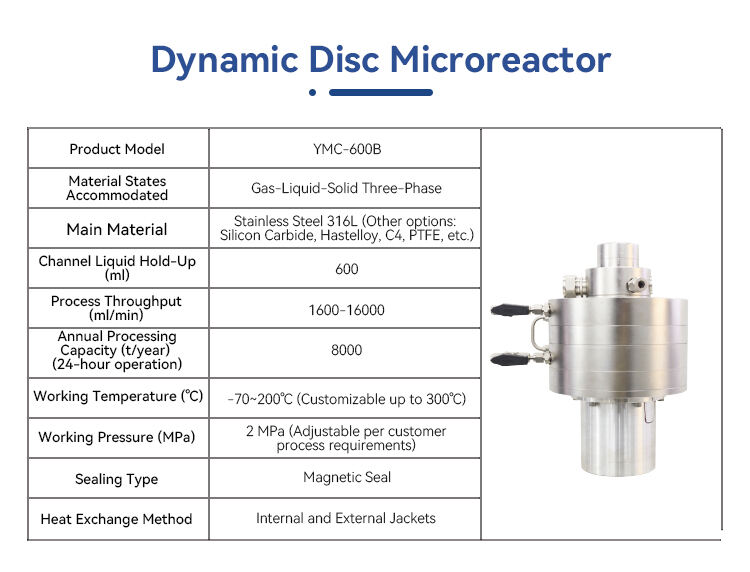

Precise control of reaction temperature and reaction time, rapid and safe reaction process, large specific surface area, homogeneous mixing of materials, energy saving and emission reduction, compact structure, no amplification effect.

● Reaction equipment size is small, fast mixing of materials, mass and heat transfer efficiency, easy to achieve the process of strengthening.

● Residence time distribution is narrow, the system responds quickly, the process repeatability is good, product quality is stable.

● Parameter control is accurate (including concentration distribution, temperature distribution and pressure distribution, etc.), easy to automate the control.

● Almost no amplification effect, can be quickly scaled up.

● Low on-line material amount, suitable for unconventional reaction conditions (e.g. high temperature and pressure), intrinsically safe process; continuous operation, high space-time efficiency, labour saving.

According to statistics, about 18.5% of the reaction processes in chemical drug synthesis can be optimized and improved in terms of selectivity, space-time yield, safety and economy by continuous flow microreaction technology.

Product Features

● Internal high shear structure, high-speed mixing impeller to ensure uniform material, high product stability.

● Suitable for reactions involving or generated by viscous liquid materials, solid phase, and can be added to suspension materials.

● High mixing efficiency, can form micro and nano particles, strengthen the reaction, prevent clogging.

Technical Advantages

● High mass and heat transfer efficiency, high mixing effect

● Precise process control, in-line inspection, modularity, automation

● Reduced side effects, micron-sized channel design

● Small reaction volume and small liquid holding capacity

● Maximum pressure resistance 40MPa, corrosion resistance (silicon carbide/Hastelloy)

● Low energy consumption and low catalyst usage

● Less three wastes, less liquid holding capacity

● Less amplification effect, fast process validation

● High-temperature resistant, diversified materials (316L/Hastelloy, etc.)

● Long catalyst life and high system stability

User Value

● High product yield and high production efficiency

● Short production cycles and rapid scale-up of production

● High product purity and selectivity

● Small footprint and intrinsically safe

● Adaptation to hazardous processes such as nitrification/chlorination

● Low integrated investment and low cost of use

● Environmental compliance and low safety risk

● Rapid industrialisation and reduced R&D costs

● Covering pharmaceuticals/electronic chemicals, etc.

● Long-term operating cost optimisation