El microrreactor de flujo continuo YHCHEM utiliza una estructura interna única para formar un flujo turbulento rápido de materiales internos, lo que puede mejorar la mezcla de fluidos, mejorar la transferencia de masa y la transferencia de calor, y es adecuado para reacciones multifásicas y reacciones en condiciones de alto riesgo o duras. Según diferentes escenarios, brindar servicios personalizados en un solo lugar tiene como objetivo acortar el tiempo de reacción, reducir el desperdicio de recursos, mejorar la calidad y pureza del producto, eliminar los riesgos de seguridad, reducir la contaminación ambiental y lograr una ampliación sin problemas del laboratorio a la producción industrial. El microrreactor de flujo continuo Yuanhuai puede realizar reacciones en una variedad de diferentes tipos y condiciones de reactores. Los componentes del sistema modular son flexibles y fáciles de usar y son adecuados para sulfonación, formato, hidrogenación, nitración, oxidación, esterificación y diazotación. Estas reacciones se utilizan ampliamente en productos químicos finos, intermedios farmacéuticos, nanomateriales, materiales poliméricos y otras industrias.

Seis grandes ventajas que respaldan a la industria química

● Procesos aplicables

Nitración, oxidación, cloración, fluoración y otros 18 procesos químicos peligrosos bajo supervisión clave.

● Campos de aplicación

Los campos de aplicación son amplios y abarcan productos farmacéuticos, agroquímicos, tintes, fragancias, productos químicos electrónicos y más.

● Opciones de materiales

Hay una variedad de materiales disponibles, incluido acero inoxidable 316L, carburo de silicio (SiC), Hastelloy, acero inoxidable C4, PTFE y más.

● Funciones opcionales

Alimentación de sólidos, pesaje y dosificación, detección de pH y análisis en línea.

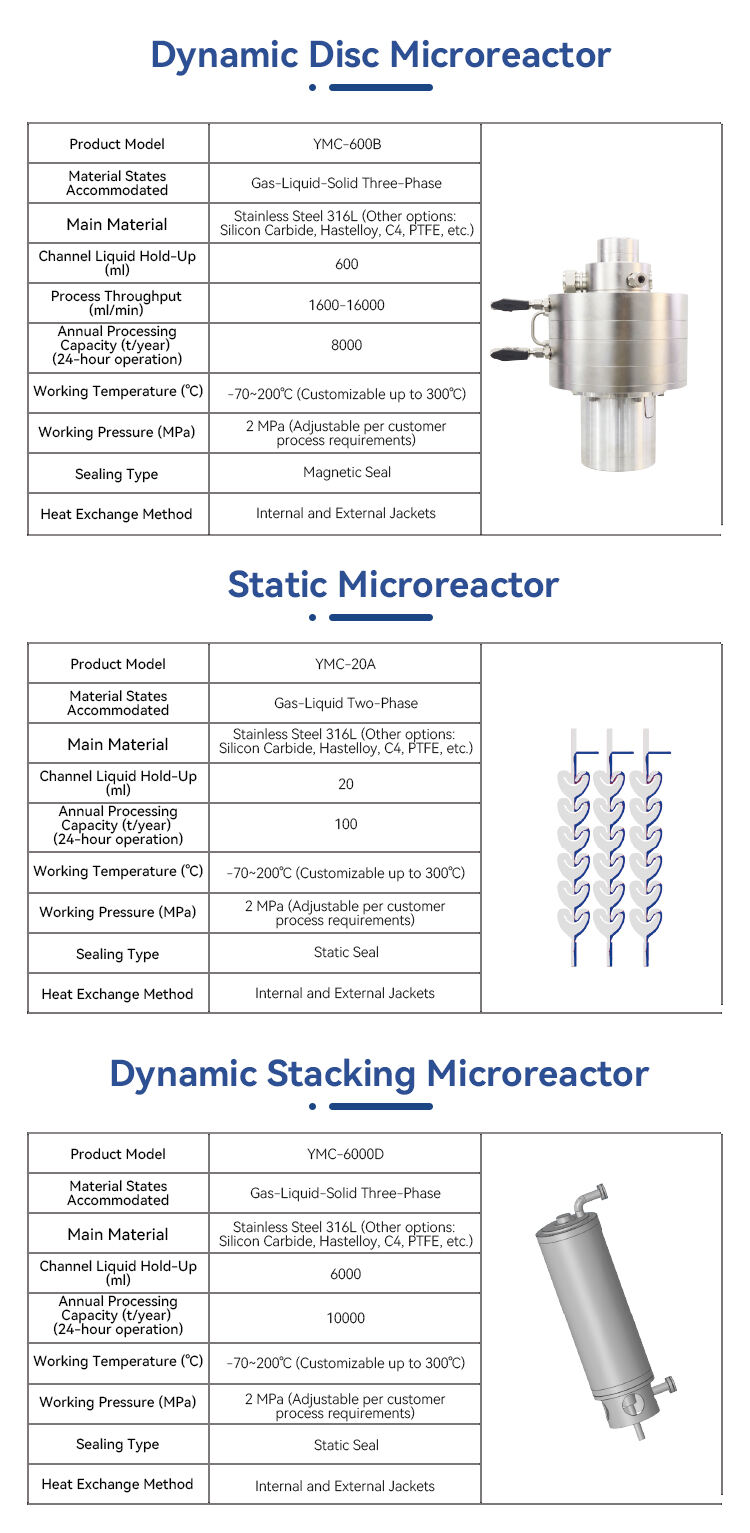

● Varios modelos

Se encuentran disponibles para su selección reactores de disco dinámico, microcanales estáticos, reactores tubulares y reactores de lecho fijo.

● Procesos personalizados

Soluciones de procesos integrales para reacciones sólido-líquido, reacciones líquido-gas, extracción, destilación, secado y otros sistemas.

Ventajas tecnicas

● Alta eficiencia de transferencia de masa y calor ● Control preciso del proceso

● Reacciones secundarias reducidas ● Efectos mínimos de ampliación

● Ciclo de producción corto ● Volumen de reacción pequeño

● Presión máxima hasta 40 MPa ● Temperatura de funcionamiento hasta 300°C

● Rangos de 10 a 1000 micrones ● Capacidad de retención de líquido de 10 a 6000 mL

● Rendimiento de mezcla superior ● Monitoreo en línea conveniente

● Diseño modular ● Automatización

● Excelente resistencia a la corrosión, adecuado para compuestos de alto pH y ácido fluorhídrico.

● Acero inoxidable, carburo de silicio, Hastelloy y otros.

Valor del usuario

● Baja inversión integral ● Bajo consumo de energía

● Alto rendimiento del producto ● Tamaño reducido

● Alta pureza del producto ● Bajo costo operativo

● Alta selectividad del producto ● Uso mínimo de catalizador, larga vida útil

● Alta eficiencia de producción ● Mínimo desperdicio

● Pequeña retención de líquido, intrínsecamente seguro ● Escalabilidad rápida

Los campos de aplicación

● Productos farmacéuticos e intermedios químicos

● Pesticidas

● Nuevos materiales

● Nueva energía

● Industria militar

● Productos químicos finos

● Tintes

● Fragancias y Sabores

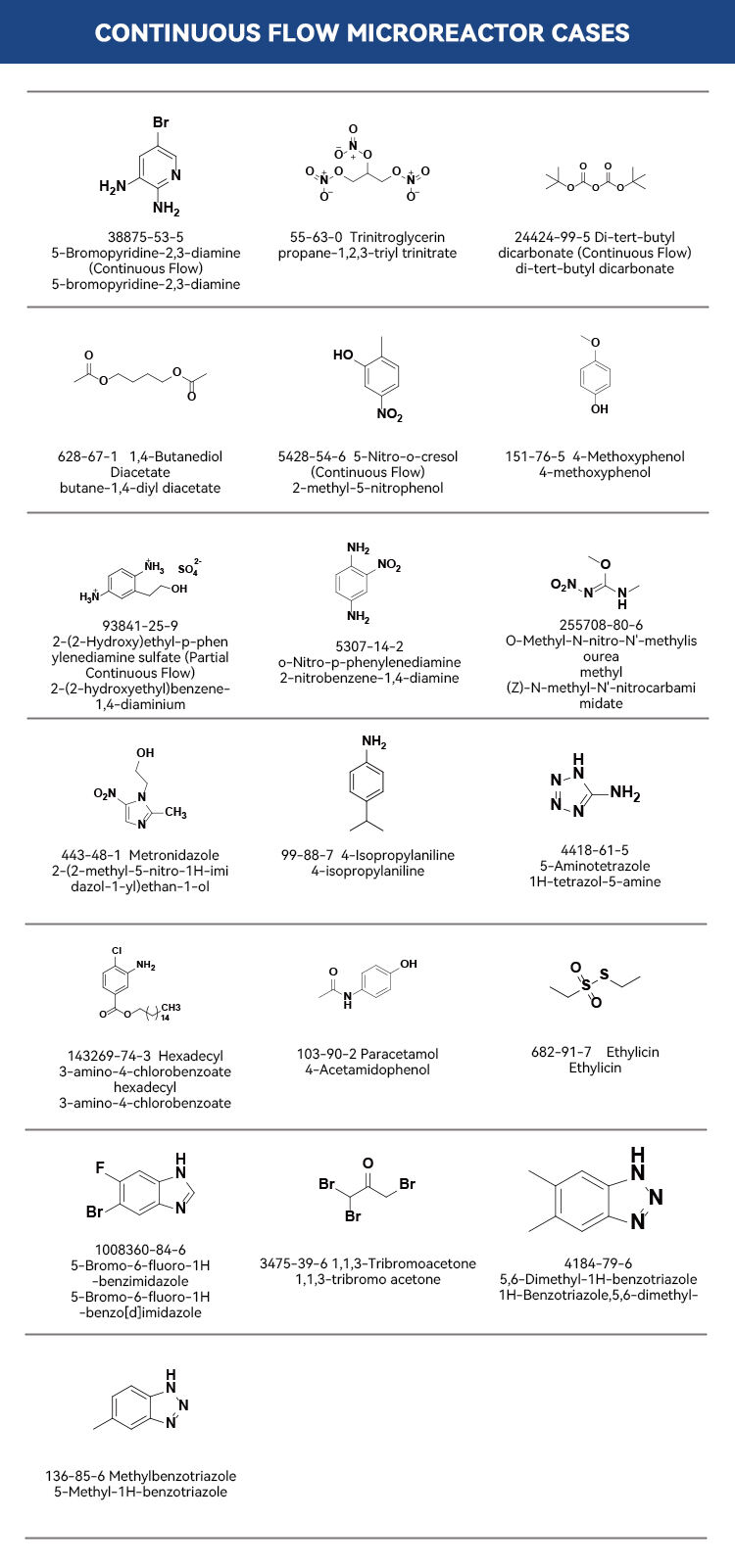

● Nitración, Sulfonación, Diazotización, Oxidación, Fluoración, Hidrogenación, Cloración, Halogenación, Brominación, Polimerización, Ciclización, Isomerización, Esterificación, Reacción de Grignard, Aminación, Alquilación, Hidroxilación, Neutralización Ácido-Base