Höyrydistillointilaitteen edut Höyrydistillointilaitteeseen on toinen tyyppi distillointilaitetta, jota käytetään komponenttien kanssa korkeilla kiehumislämpötiloilla. Lopulta tämä yksikkö tuottaa elinajan, joka on melko pitkä, mikä tekee siitä keskeisenä osana sovelluksissa useimmissa teollisuuden aloissa. Höyrydistillointilaitos on kykenevä termisesti irrottaamaan aineita korkealla kiehumislämpötilalla, pääasiallinen etu olemaan se, että tämä voidaan saavuttaa lämpötiloilla, jotka ovat alempi kuin ilmakehädistillointi. Tämä tekee myös distillointiprosessista huomattavasti energiatehokkaamman, mikä johtaa suuriin säästöihin energian kulutuksessa. Lisäksi matalampi lämpötila vähentää todennäköisyyttä termisen hajoamisen tapahtumasta sen koostumuksen osalta, mikä tarkoittaa parempia laatuja tuotteissa.

Edistys tyhjiödestilaatioteknologiassa on tehnyt ne paljon tehokkaammiksi ja tehokkaimmiksi. Uudet mallit sisältävät nyt uusimmat ominaisuudet, jotka mahdollistavat niiden käytön helposti, turvallisesti ja myös erittäin tehokkaasti. Yksi näistä innovaatioista, joka ansaitsee erityisen maininnan, on tietokoneohjattujen järjestelmien käyttö, jotka tarjoavat tarkkaa destilaatiota hallitsemalla ja automatisoimalla. Tämän lopputavoitteen saavuttamiseksi prosessi on todella optimoituna huipputehokkuuteen ja laadun parhaaseen käytäntöön samalla kun virheet vähennetään mahdollisimman lähelle nollaa.

Yksi tärkeimmistä asioista on varmistaa, että kaikki teollinen laiteisto toimii turvallisesti, ja tämä pätee myös kun puhumme tyhjännyssäiliöstä. Uudemmat mallit ovat varustettu useilla turvallisuusominaisuuksilla, jotka säilyttävät ne turvallisina. Laite sammutetaan automaattisesti minkään hätätilanteen tapauksessa, varmistamalla, ettei haittaa pääse käyttäjään tai laitteeseen. Yksikön suunnittelu pitää tällaista materiaalia hyvin sisällä ja höyryttää sitä hallituissa olosuhteissa. Tämä laite tulisi käsitellä käyttämällä sopivaa suojavarustetta.

Käyttääksesi höyrydistillaatiolaitetta oikein, sinun täytyy tuntea se erityinen laite ja kaikki mitä siihen kuuluu. Aloittaaksesi, sinun täytyy käyttää laitetta päälle ja antaa se laskea sopiviin höyrytason tasoihin. Distilloidaksesi aineksen sen lisätään sarakkeeseen. Tietokonehallinta säätää automaattisesti lämpötilan ja paineen laitteessa tehdäkseen distillaatio prosessista tehokkaampaa (alhainen polttoaineenkulutus) mutta hyvin korkealaatuisena. Veden varasto kontti käytetään jälleen kondensoimaan höylyn, mistä distillaatia voidaan kerätä.

Tyhjännyssäiliöyksikön on myös ylläpidettävä ja huollettava säännöllisesti parhaan suorituskyvyn saavuttamiseksi. Yksi tällaisen laitteen yleisimmistä ongelmista on saasteet ja uppoaminen, mikä tarkoittaa, että kruunut ja putket täytyy säätää manuaalisesti ajoittain tai puhdistaa. Koko yksikkö pitää tarkastaa säännöllisesti kuljetuksen tai vaurioiden merkkejä, ja se korjataan tarvittaessa. Tyhjännyssäiliöyksikön ostaminen on niin tärkeä sijoitus, että haluat varmasti hoidella sitä niin, että sen suorituskyky ja laatu pysyvät korkeina. Toinen erityiskohta on kalleiden pysäytysten ja korjausten ehkäisy.

Tuotteemme ovat auttaneet tuhansia tunnettuja yrityksiä yli 100 maassa sekä alueilla tyhjännyssäeistöjen osalta, saaden monien tunnustusten luottamuksen. Olemme sitoutuneita parantamaan tuotteitamme ja palveluitamme asiakkaiden palautteen mukaan.

Yrityksenä listattuna on vakaa taloudellinen vakaus ja kestävä kehitys kykenevät. Jatkossa noudatetaan periaatteita, jotka perustuvat markkinoiden kysyntään, edistämällä jatkuvaa tuotekerrostusta ja teknologian kehittymistä luodakseen enemmän arvoa ja mahdollisuuksia sijoittajille, asiakkaille ja työntekijöille.

Meillä on maailmanluokan teknologinen innovointi ja tutkimus- ja kehityskapasiteetti ympäri maailmaa, ja evakuointidestillaatioliitännön esittelee kansainvälisi korkeateknologisia tekniikoita, joita käytetään jatkuvassa itsenäisessä innovoinnissa ja teknologian päivityksissä. Yhteistyössä tunnettujen tutkimuslaitosten, kuten Shanghai Chemical Industry Research Institute ja East China University Science and Technology kanssa olemme perustaneet yhteisiä laboratorioita, sitoutuneina tarjoamaan asiakkaillemme kilpailukykyimpiä ratkaisuja ja tuotteita.

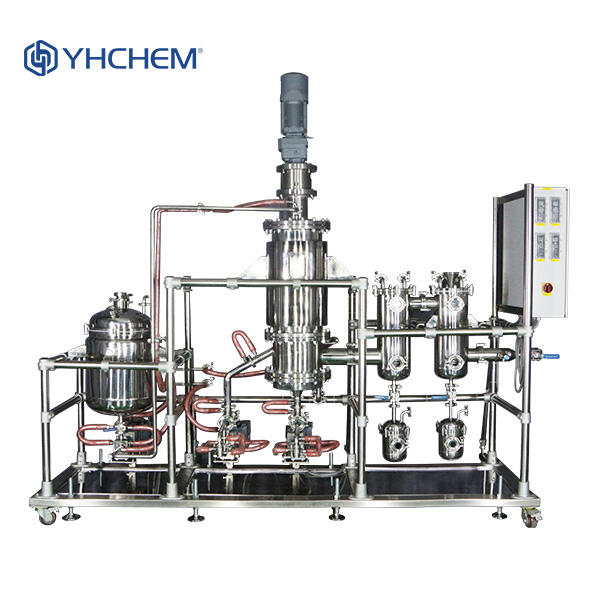

tuoteryhmä sisältää useita malleja, mukaan lukien destillointi-, reaktio- ja lämpötilavakuumidestillaattoriyksikön sekä lasialusteiden laitteet, jotka täyttävät erilaisten teollisuudenalojen vaatimukset. Monipuolisilla palvelupisteillämme tarjoamme asiakkaillemme tieteellisiä yhteenvedonpalveluita, jotka antavat nopeaa teknistä tukea myyntipalvelun jälkeen koko käyttömatkan ajan.

Erilaisia Vacuum distillation -tuotteita on käytetty monella tavalla jo vuosikymmeniä eri teollisuudenaloilla. Oli- ja kaasuteollisuudessa monitason fraktionaalinen destillaatio käytetään yleisesti raakaöljyn rafinointiin tuotteiksi kuten benziini, diesel ja makeoilut. Se käytetään myös kemikaalien, lääkeaineiden ja elintarviketeollisuuden valmistuksessa. Erittäin monipuolinen suunnitelma, joka soveltuu eri teollisuudenaloille, joissa destillaatioprosesseja tarvitaan tiettyihin tarpeisiin.