- Mion-eirí i gCás Ionadacha

- Táirgí gaolmhara

Mion-eirí i gCás Ionadacha

Forléargas

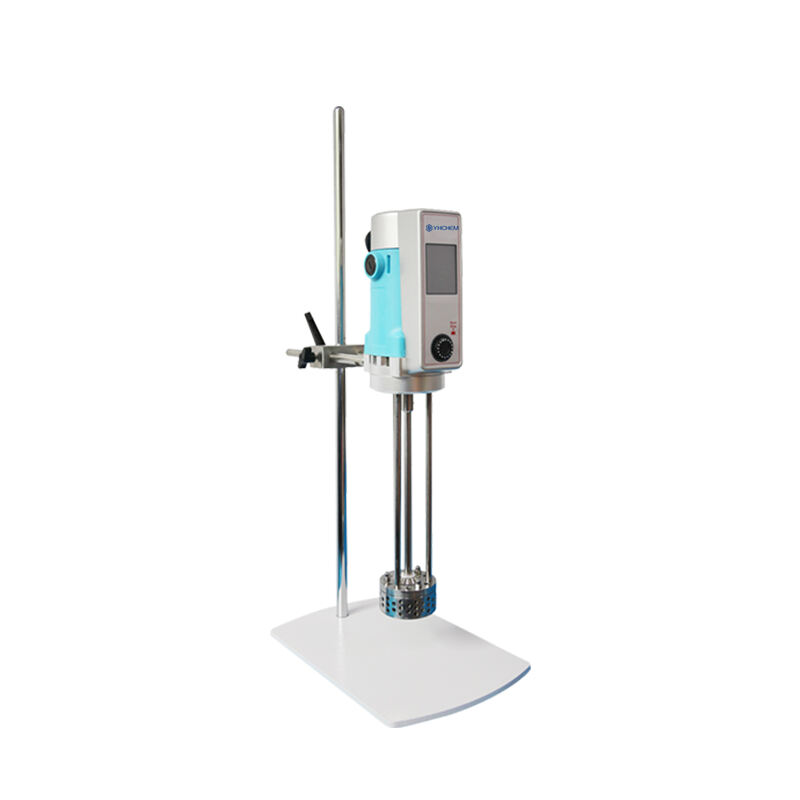

Is é an t-athrúchán snámh pharlaminteach laboratóire YHAE a mheasann rudaí agus atá cruthaithe le haghaidh micromotor uasaireachta ardshpeisialta. Is féidir leis úsáid a bhaint as é chun líonta íseal go méanviscacht agus líonta ardviscacht a ngleacadh i gcásanna laboratóire nó saorphlé, agus chun gnéithe gránula a chruthú trí shnámh agus meascadh i meán líne. Tá an ábhar cruthaithe as motor ardshpeisialta, ceann obair snámha agus meascála, agus rialtaire spéise. Tá an fhostóg ina choimhéad ar phlásca inbhféil ingearach den chéad scoth agus ar dhíchéim alamain dúnta mar thoradh ar stailéidh oibriú; tá an cheann obair cruthaithe as stainleis den chéad scoth agus léiríonn sé úsáid eiceapta i gcásanna taighde; tá an spéas oibriú rialaithe ag micropróiseáil, a chuireann cúnamh isteach go huafásach agus go héifeachtach ar athruithe spéise a chuirfí chun cinn ag athruithe lód agus scileanna fuinneoga foilsiúcháin; is déanta an cumarsáid spéis. Tá soft start ina chomhléiriú agus cosaint uathuighreacht uimhir-iompaithe de réir réigiún a chur i bhfeidhm chun cinntiú ar shlándáil na taighde agus ar oibriú iomlán faoi locht agus go continiútach le huaireanna fada. Is féidir le comhréire spéis neamhspleách an spéas meascála a chur i gcuimhne ar bith amárach i dtús an eicípse. Tugann roinnt nuiméaracha faoi fhoréig, tuiscint, curraim, fuinneog pháistí, torc fhoilsithe agus céanna eile soláthar do thaispeántas sonraí taighde. Cinntíonn feidhm rialta timpeallachta an taighde go bhfuil an timpeallacht taighde rialaithe go hiomlán.

Gnéithe

● Mótar ardmhíre, mírtheideal ciallach

Úsáidtear mótar mhicre ardmhíre chrua séimh nua-aimsire don iompar, le héadromchumhacht riartha ag úsáid micropróiseasair, a fhéadfadh éifeachtúil a chinntiú go luath cúnamh do théarmu na mírtheideala as hathruithe lódála agus hathruithe foltasa an phléidhse, cinntiú mírtheideal ciallach agus déanfaidh.

● Réigiún mírtheideala gan tograí, taispeántas digiteach

Is féidir an mírtheideal a shuímhniú gan dearmad, pléaráil leis an gcás atá ann go mbeidh éifeachtúil a chinntiú go luath mírtheideal mícheart. Taispeántar an foltas, an tuarascálacht, an tsruth, an chúlra fhoirmiúil agus an chúlra torcanna amach in real time, a chur i bhfeidhm don scagaire sonraí thíos.

● Homogenization éifeachtúil agus milsiú, slán agus comhiantaithe

Úsáidtear plastics ingineacha ardchaighdeála agus dí-chástáil chóras allaimh don ghné chrua, cinntiú oibriú staidiúil; tá soft start agus cosaint uathuile faoi láthair cuimsitheach isteach chun cinntiú na sláinte agus an sábháilteacht don oibriú iomlán-fhorleathan i gcónaí.

Úsáidtear mótar mhicre ardmhíre chrua séimh nua-aimsire don iompar, le héadromchumhacht riartha ag úsáid micropróiseasair, a fhéadfadh éifeachtúil a chinntiú go luath cúnamh do théarmu na mírtheideala as hathruithe lódála agus hathruithe foltasa an phléidhse, cinntiú mírtheideal ciallach agus déanfaidh.

● Réigiún mírtheideala gan tograí, taispeántas digiteach

Is féidir an mírtheideal a shuímhniú gan dearmad, pléaráil leis an gcás atá ann go mbeidh éifeachtúil a chinntiú go luath mírtheideal mícheart. Taispeántar an foltas, an tuarascálacht, an tsruth, an chúlra fhoirmiúil agus an chúlra torcanna amach in real time, a chur i bhfeidhm don scagaire sonraí thíos.

● Homogenization éifeachtúil agus milsiú, slán agus comhiantaithe

Úsáidtear plastics ingineacha ardchaighdeála agus dí-chástáil chóras allaimh don ghné chrua, cinntiú oibriú staidiúil; tá soft start agus cosaint uathuile faoi láthair cuimsitheach isteach chun cinntiú na sláinte agus an sábháilteacht don oibriú iomlán-fhorleathan i gcónaí.

Feidhmíocht típici

Is féidir leis an gcuallach snámha phléidéil úsáid a bhaint amach do scagadh comhréir i réim biotéicneolaíochta, fógartú samplóid i gcampas farmasiúcail, tréitniú enzaim i réim an bíodúchais, agus feirmeacha líofa-líofa nó líofa-sólaid i gcampas na n-farmasiúcaigh, na gcosmaitíce, na ndathanna agus na n-dulachán pétroleam. Scannann sé an meán-eachtarach faoi thrí chás de shnámh, impiact laghdha, agus leathnú síntiú sa bhlada líofa, idirníosann sé míreanna níos rialta agus caithfidh sé nó briseann sé cúlraíocht leis an bhfhlad líofa. Is úsáideach go sóna é san fhreastal ar phróiseas mar shampla iompartha agus snámha i lán-tionscnamh béil mar shampla dlúththéad,raithniú,samplacha cosmaitíce agus farmasiúcaigh.

Paraiméadar Táirge

| Múnla | HAE-500S-70G | HAE-500S-90G |

| Speisifící cuspóireachta | 220V,50/60Hz,1P | |

| Cuir isteach an fhoirteán (W) | 850 | 1400 |

| Machnaimh poist (W) | 500 | 800 |

| Casmhóiminte rátáilte (N·m) | 35 | 70 |

| Córas oibre | S1 (laghdú) | |

| Modh riarthroidhe | Bainisteoir tiormhainne taice | |

| Rang cáiliúcháin luas (gan lód)(c/m) | 1000~14000 | 1000~13000 |

| Dlí rialaithe luais | Gan eileadán | |

| Taispeántas uimhriúil luais | TFT-LCD | |

| Rang rialaithe ama(nuach.) | 1~1000 | |

| Taispeántas cumha tréith i gcás réaltaimh | Tá | |

| Taispeántas i gcás réaltaimh de foltáil, tíos, tuice agus neamhspleáchacht | Tá | |

| Funtion cosaint íocair | Tá | |

| Torcais uasail chun cinn an phríomhshruthaigh (N·m) | 35 | 70 |

| Luas líneár uasal an rathaid (m/s) | 18 | 22 |

| Méid mháistreachta an phríomhshruthaigh | SS 304 acer ghlas | |

| Diaméad an phríomhshruthaigh (mm) | 70 | 90 |

| Airde ísál iontrála díomhain (mm) | 50 | |

| Airde imirt uasal i dteideal (mm) | 235 | |

| Cumraíocht staidiartha (m ㎡) | 5,20,50 | |

| An méid próiseála (uisce) (ml) | 500-40000 | 800-60000 |

| An chruaiteacht próiseála is airde (mPa.s) | 8000 | |

| Ceadóigh téamh fadomhain ( ℃) | ≤40 | |

| Ceadóigh fliuchas comhréidh (%) | ≤80 | |

| Méid fo-sgríofa (mm) | 215*315*700 | 215*315*700 |

| Cúlra comhpleite an mhachanála (cag) | 9.2 | 10 |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN