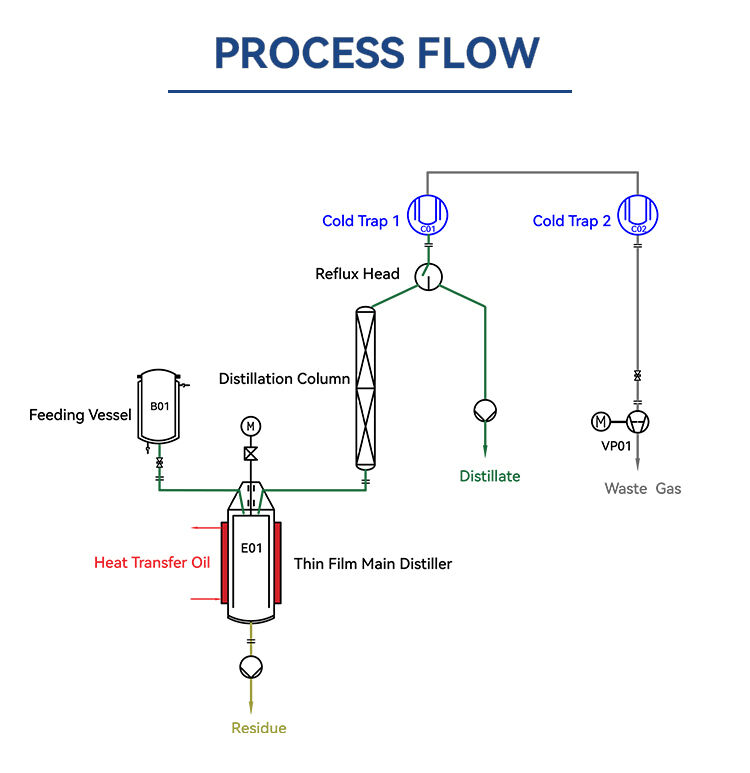

♦♦WORKING PRINCIPLE

The material enters the main evaporator from the feeding tank, and is scraped intoa very thin and turbulent liquid film by the film scraper, and pushes downward in a spiral shape. The light product components escaping from the heating surface enter the rectification column upwards and carry out mass transfer and heat transfer between gas and liquid. The product materials are condensed by the condenser,and if the purity is not enough, they will flow back. Finally, the high purity products will be collected.

PRODUCT DESCRIPTION

Thin film distillation column is a coupling device between thin-film evaporator and distillation column.ln the process of distillation, thin film distillation column can solve the problem of thermal decomposition of heat-sensitive materials, which caused by too high temperature in the tower bottom and too long residence time inthe reboiler. lt prevents deterioration reactions such as decomposition, polymerization and oxidation of materials when heated, and effectively protects the characteristics of product materials. At the same time, compared with the traditional thin-film evaporator, the thin-film distillation column increases the function of distillation, which can better improve the purity of products and reducemore purification process steps. The excellent characteristics of negative pressure film scraping and rectification of thin film distillation column can be widely used in biopharmaceuticals, food fields, plant extraction and chemical industries.

Technical Specification:

| Model | YWT-60 | YWT-80 | YWT-100 | YWT-150 | YWT-200 |

| Volume of charging tank (L) | 0.5 | 1 | 1 | 2 | 5 |

| Tower height (m) | 1 | 1 | 1 | 1 | 2 |

| Condensing area (m²) | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 |

| Rotation speed range (rmp) | 50-500 | ||||

| Operating pressures (mbar) | ≤0.001 | ||||

| Working temperature range (℃) | ≤300 ℃ | ||||

| Input voltage | 220V/1P | ||||

PRODUCT DETAILS

♣1.Supply Customized Services

Can supply customized service according to customer's mate-rial characteristics

♣2.Low distillation temperature and high vacuum degree

The vacuum environment with negative pressure can avoid the decomposition and poymerization of heat-sensitive materials, and reduce the distillation temperature of materials which with high boilingpoint. The material will have short residence time and high heat transfer efficiency

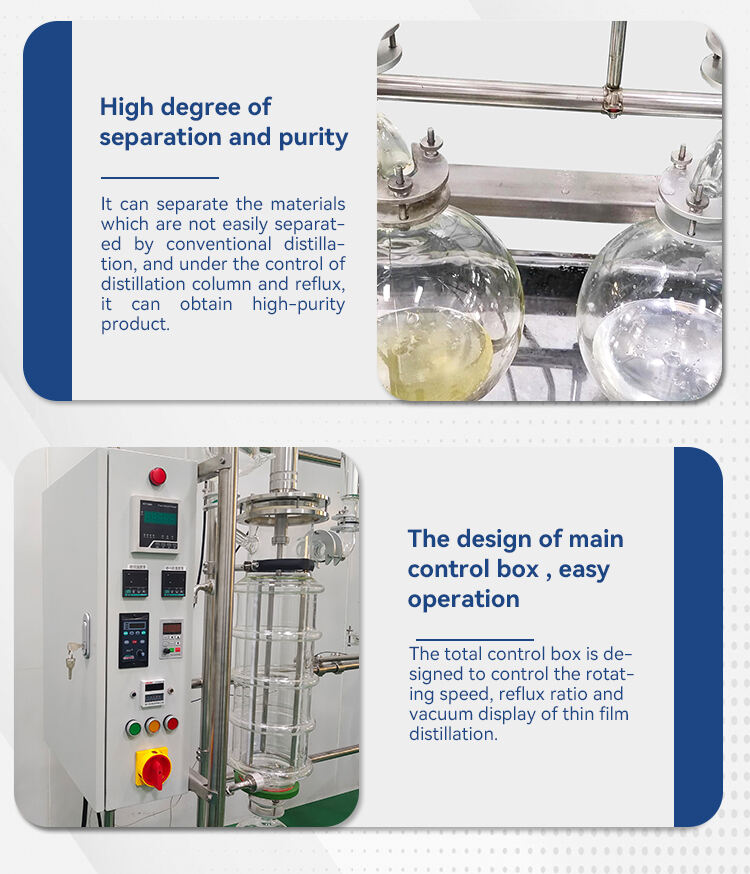

♣3.High degree of separation and purity

lt can separate the materials which are not easily separated by conventional distillation, and under the control of distillation column and reflux,it can obtain high-purity product.

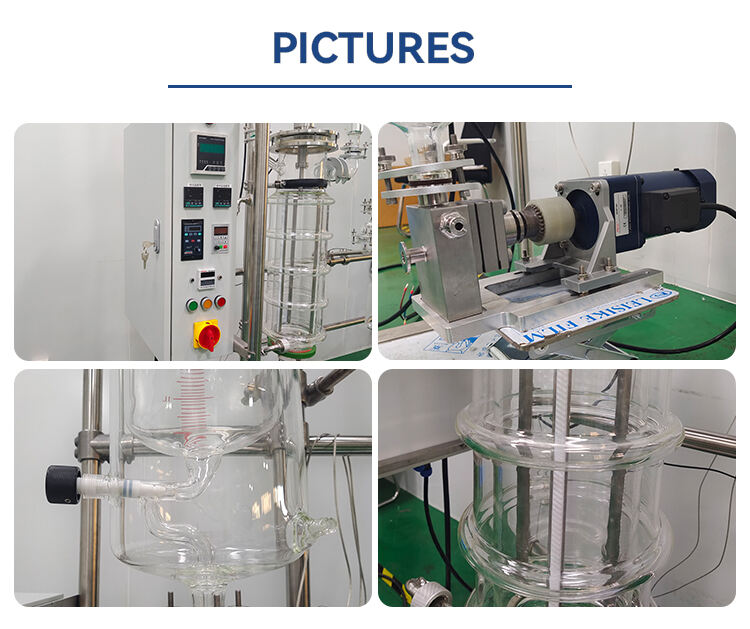

♣4.The design of main control box , easy operation

The total control box is designed to control the rotating speed, reflux ratio and vacuum display of thin film distillation.

APPLICATION FIELDS

♣Biopharmaceutical

♣Plant extraction

♣Food

♣Chemical industry

FLEXIBLE GLASS STRUC

♣Cold Trap 1

♣Reflux Head

♣Distillation Column

♣Feeding Vessel

♣Distillate

♣Cold Trap 2

♣Waste Gas

♣Heat Transfer Oil

♣Thin Film Main Distiller

♣Residue

♣Heating circulator

♣Cooling circulator Gear pump

♣Vacuum pump

♣Thin Film Distillation Column

Our friendly team would love to hear from you!