Isopropyl Nitrate (IPN) is a common liquid nitrate ester energetic material that plays an important role in defense, medicine, and industry. In the defense sector, IPN is often used as a primary component of fuel-air explosives. Due to its unique advantages of low toxicity, low corrosiveness, and low sensitivity, it is also widely utilized in applications such as propellants, sensitizers, and diesel additives.

However, the existing batch synthesis method for IPN involves using nitric acid and isopropanol as raw materials, along with the addition of urea and ammonium nitrate. The reaction occurs at 100°C to produce IPN, with a yield of 85%. This method has several drawbacks, including complex reaction steps, high and difficult-to-control reaction temperatures, the need for slow dripping of raw materials below the liquid surface (increasing operational difficulty and danger), and relatively low yields.

YHCHEM SOLUTION

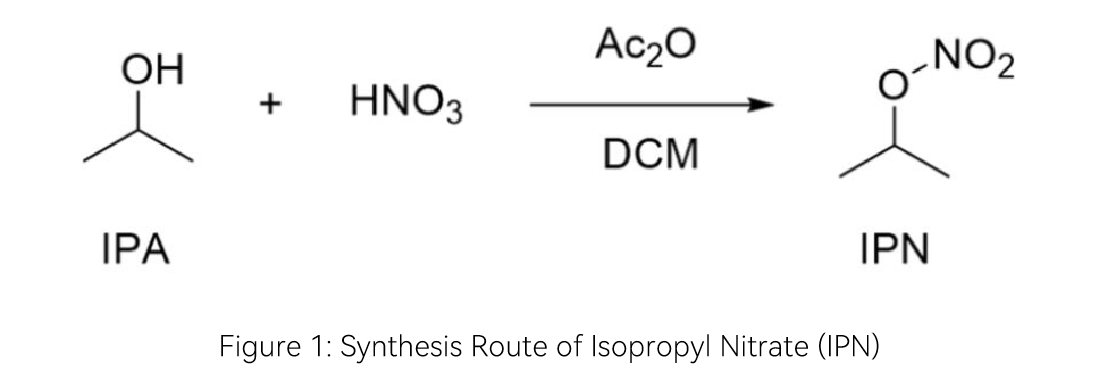

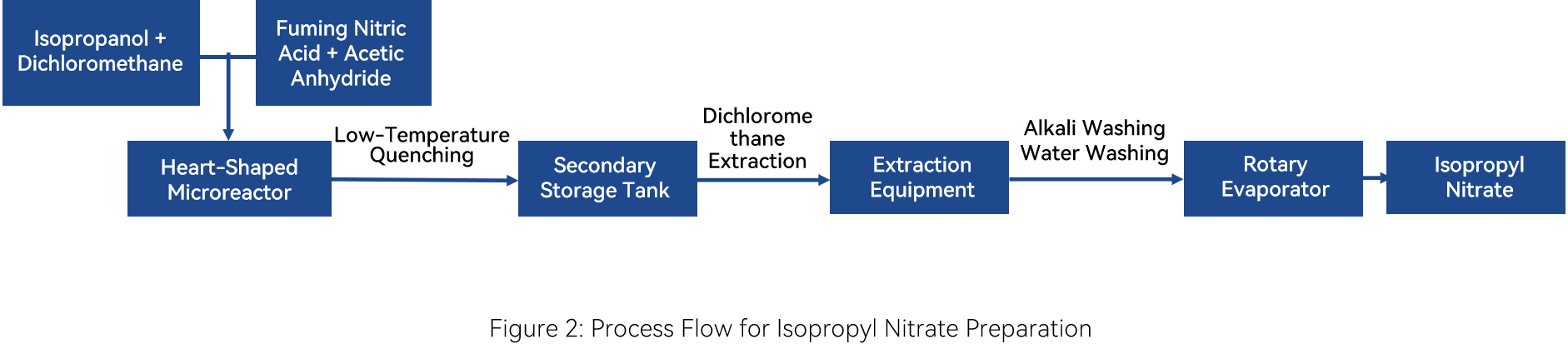

To address the issues of poor reaction control and high reaction temperature in batch reactors, engineers at YHCHEM have developed a solution utilizing a heart-shaped microchannel reactor. In this process, isopropanol is used as the raw material, dichloromethane as the solvent, and fuming nitric acid and acetic anhydride as nitrating agents to synthesize isopropyl nitrate. The diagram below illustrates the synthesis route and process flow.After multiple adjustments to the process details by the experiment team, the conversion rate of isopropyl nitrate can reach as high as 99.8%, with a yield of up to 96%. This process demonstrates high conversion rates, high yields, and reduced production of waste acid, making it highly promising and valuable for industrial-scale applications.