Il CBD ha molteplici attività farmacologiche, tra cui proprietà antiinfiammatorie, antioxidanti e neuroprotettive. Viene utilizzato ampiamente nei campi della medicina, della cosmesi e degli alimenti. Yuanhuai ha sviluppato una soluzione comprensiva per il processo produttivo f...

Condividere

Il CBD ha molteplici attività farmacologiche, tra cui effetti anti-infiammatori, antioxidanti e neuroprotettivi. Viene ampiamente utilizzato nei settori della medicina, della cosmesi e degli alimenti. Yuanhuai ha sviluppato una soluzione di processo produttivo completa per il CBD, combinando la sintesi con microreattore a flusso continuo con la distillazione molecolare o la rettificazione per la purificazione. Durante la fase di sintesi, la tecnologia avanzata del microreattore garantisce reazioni rapide con alto rendimento e selettività, riducendo al contempo la formazione di prodotti secondari. Nella successiva fase di purificazione, viene applicata la distillazione molecolare o la rettificazione per separare in modo efficiente il CBD termosensibile a basse temperature, garantendo l'alta purezza e qualità del prodotto finale. Questo processo produttivo integrato non solo migliora l'efficienza della produzione, ma garantisce anche la coerenza e affidabilità dei prodotti a base di CBD, soddisfacendo gli elevati standard richiesti dalle industrie farmaceutica e sanitaria.

PRINCIPIO DEL PROCESSO

Equazione di Reazione:

Il CBD viene ciclizzato in delta-9 THC utilizzando AlCl3 come catalizzatore.

CBD + AlCl3 ---> delta-9 THC

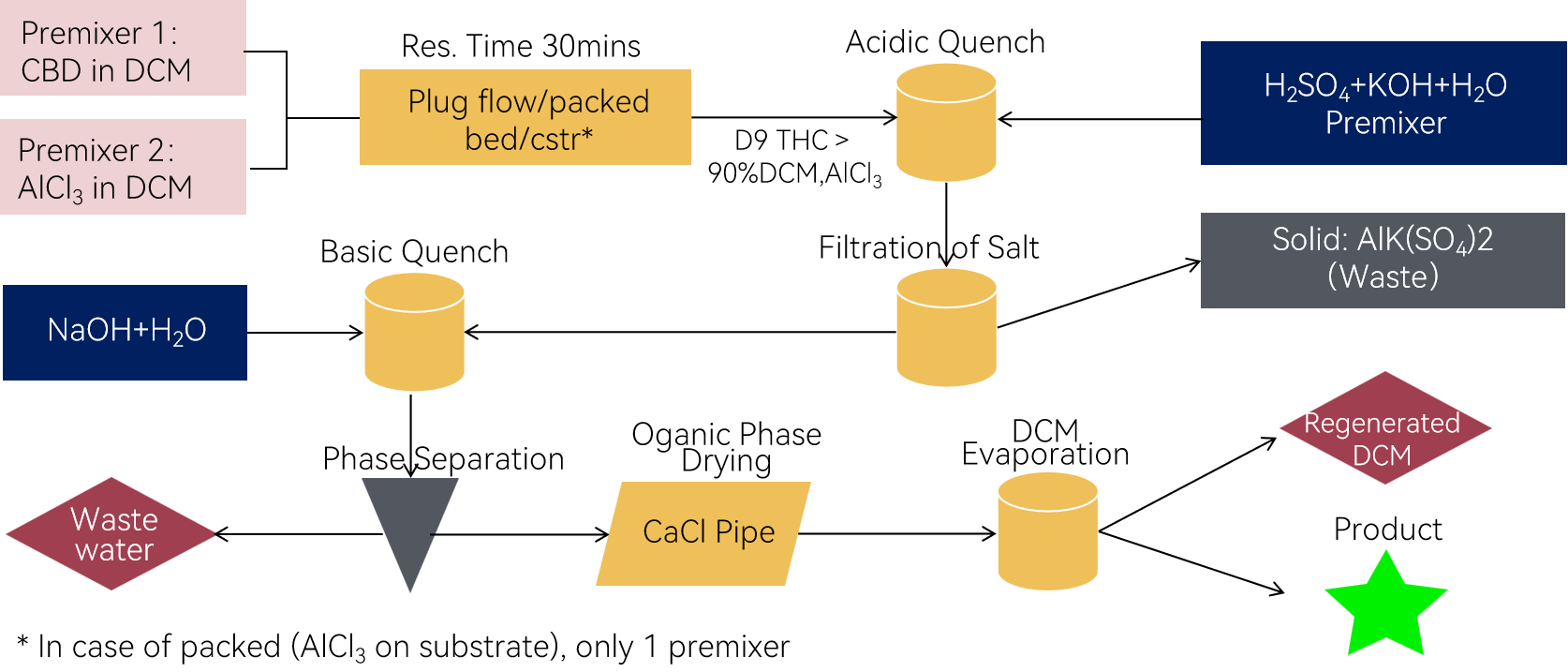

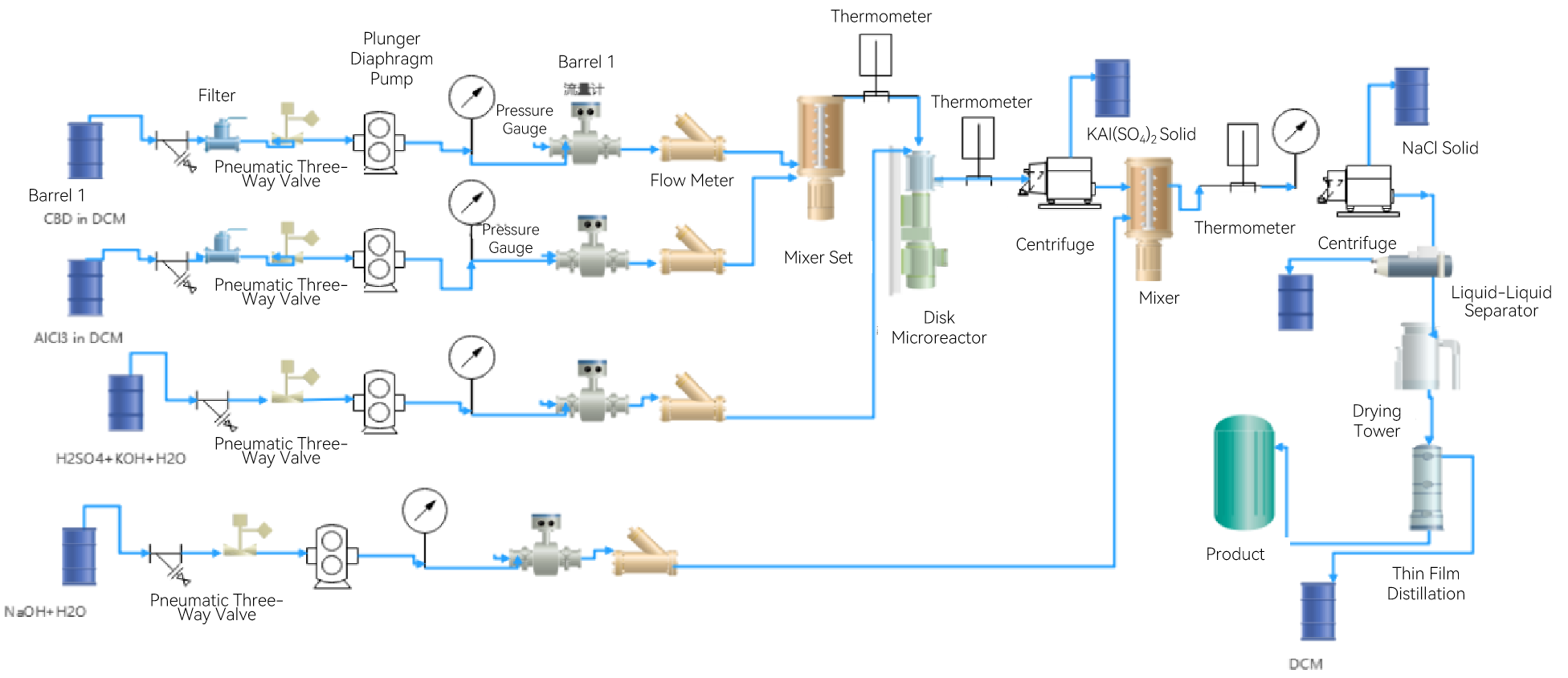

DESCRIZIONE DEL FLUSSO DI PROCESSO

1.Pre-trattamento: L'AlCl3 viene sciolto nel solvente DCM (diclorometano) per preparare una sospensione, e il CBD viene sciolto in DCM come materiale per la reazione.

2.Reazione Chimica nel Microreattore Dinamico: La sospensione viene introdotta nel microreattore dinamico dove avviene la reazione chimica sotto condizioni controllate di temperatura e pressione per evitare l'ebollizione del DCM e inibire le reazioni secondarie.

3.Arresto con Acido: Dopo che la reazione è completata, per impedire la formazione di idrossidi di alluminio/ossidi, la miscela reattiva viene rapidamente arrestata in un microreattore a disco con un agente di arresto pre-misto di H2SO4 (acido solforico) e KOH (idrossido di potassio).

4.Separazione Solido-Liquido: Il prodotto della reazione raffreddato viene sottoposto a separazione solido-liquido utilizzando un centrifuga Yuanhuai, ottenendo scarti solidi AIK(SO4)2 (solfato di alluminio e potassio) e una soluzione contenente CBD.

5.Raffreddamento Basico e Separazione Fase: Si aggiunge una soluzione di NaOH (idrossido di sodio) alla fase liquida per il raffreddamento basico in un microreattore a tre stadi, al fine di neutralizzare eventuali acidi residui e promuovere la separazione delle fasi organica e acquosa.

6.Lavaggio: La fase organica viene lavata sequenzialmente con acqua, NaHCO3 (bicarbonato di sodio), NaCl e un ultimo lavaggio con acqua per purificare la fase organica.

7.Trattamento Posteriore: La fase organica viene essiccata e filtrata attraverso carbone attivo per rimuovere i catalizzatori residui e prevenire l'isomerizzazione durante la distillazione.

8.Recupero del Solvente e Purificazione del Prodotto: Il DCM viene evaporato utilizzando un evaporatore a film sottile e attrezzature per la distillazione molecolare, ottenendo così delta-9 THC puro. Il DCM evaporato viene trattato correttamente per il riciclaggio, garantendo un'efficiente utilizzazione delle risorse.

9.Controllo della Qualità del Prodotto: Durante tutto il processo produttivo, viene utilizzato un monitoraggio online per tenere traccia in tempo reale degli attributi chiave di qualità, assicurando che il prodotto rispetti le specifiche e gli standard prestabiliti.

Questo processo continuo non solo aumenta l'efficienza produttiva e il rendimento del CBD con un alto tasso di conversione in delta-9 THC, ma riduce anche al minimo la formazione di delta-8 THC. Inoltre, garantisce la qualità del prodotto e la sostenibilità ambientale, aderendo ai principi della chimica verde nella produzione chimica moderna.