Lactic acid, scientifically known as α-hydroxypropionic acid, is widely found in nature and has a wide range of applications in industries such as food, medicine, cosmetics, environmental protection, agriculture , chemicals, electronics, and bi...

Share

Lactic acid, scientifically known as α-hydroxypropionic acid, is widely found in nature and has a wide range of applications in industries such as food, medicine, cosmetics, environmental protection, agriculture , chemicals, electronics, and bio-based degradable materials . Polylactic acid obtained by polymerization of lactic acid monomers as a bio-based degradable material has the advantages of good biocompatibility, low toxicity, and cheap raw materials, and is of great significance in environmental protection and new materials industries.

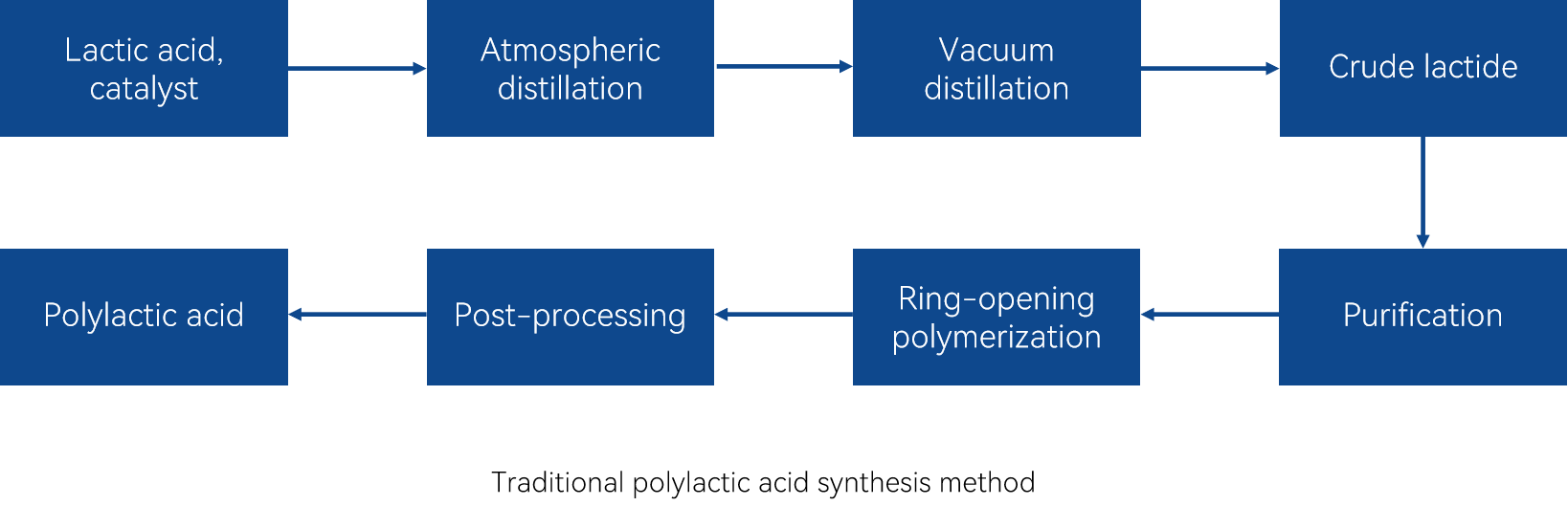

Traditional polylactic acid synthesis method

The raw material of the traditional polylactic acid synthesis method is lactide (cyclic dimer of lactic acid), which is purified by atmospheric and vacuum distillation, and then obtained by ring-opening polymerization and post-treatment. The high cost has affected the widespread application of polylactic acid.

YHCHEM SOLUTION

At present, the preparation of polylactic acid mostly adopts a one-step synthesis method by direct polymerization of lactic acid. This method puts forward higher requirements on the purity of lactic acid. The lactic acid purified by traditional ion exchange, membrane filtration and other technologies can no longer meet the demand in terms of color and purity. Yuanhuai molecular distillation equipment, as a high vacuum distillation equipment, performs liquid-liquid separation according to the difference in the average molecular free path of the material. The material is heated to a small extent and has a short residence time on the heated surface. It can effectively separate heat-sensitive and easily oxidized substances. The purity of lactic acid after molecular distillation purification can reach more than 95%, and the yield can reach 70%.