Polymerization reactions place high demands on the heat transfer performance and mixing capacity of reactors. The shortcomings of traditional batch reactors in these aspects have become one of the bottlenecks in achieving high-performance polymers. On the other hand, microchannel reactors can enable controllable multiphase micro-scale flows, enhancing the mixing, mass transfer, and heat transfer processes during polymerization reactions. They strictly control reaction time and achieve modular assembly of reaction units, thereby perfectly overcoming this bottleneck. Compared to traditional batch reactors, these features give microchannel reactors significant advantages in controlling polymer molecular weight distribution, simplifying reaction conditions, improving reaction selectivity, and regulating polymer molecular structure and macroscopic morphology.

Polyethylene glycol (PEG) is a water-soluble polymer synthesized from ethylene oxide and ethylene glycol.The PEG molecule contains a large number of ethoxy groups, which can form hydrogen bonds with water and mix with water in any ratio. PEG is mild in its effects, causes few adverse reactions, and holds broad market prospects as a pharmaceutical excipient. Currently, industrial-scale production of narrow- distribution PEG generally uses traditional batch reactors for polymerization. While this process can produce PEG with a dispersity index below 1.05, the product is still a mixture of different molecular weights. Even under high-purity raw materials and stringent anhydrous process conditions, polymerization in traditional batch reactors cannot achieve a single-distribution PEG. Only microchannel reactors can synthesize PEG with a single molecular weight distribution.

YHCHEM SOLUTION

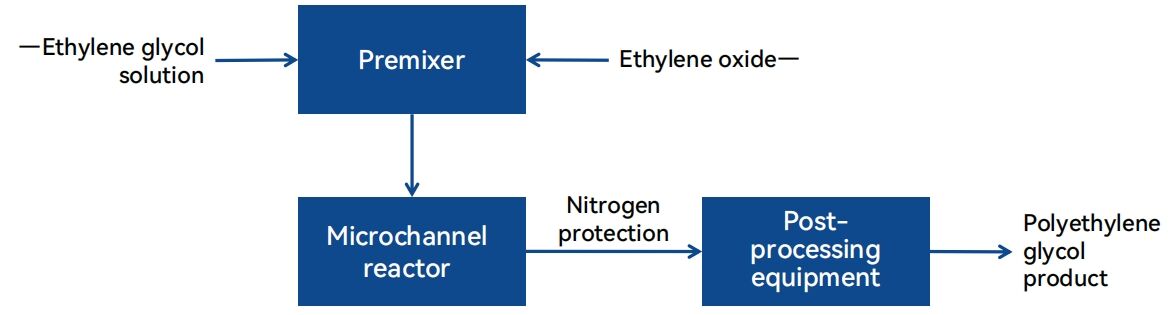

The YHCHEM Technology team used ethylene glycol and ethylene oxide as raw materials, adopting a process of mixing first, followed by reaction and subsequent treatment, to produce PEG products with yields as high as 95%. The specific process flow is as follows: