Model |

YFR-10SEX |

YFR-20SEX |

YFR-30SEX |

YFR-50SEX |

YFR-100SEX |

YFR-200SEX |

YFR-300SEX |

Net Volume(L) |

10 |

20 |

30 |

50 |

100 |

200 |

300 |

Material |

The part contact with the material is SUS316, and the rest is S30408 |

||||||

Stirring Motor |

Motor power 200W Inerter, 80 460 rpm |

Motor power 370W Inerter, 80 350rpm |

Motor power 750W Inerter, 80 350rpm |

Motor power 1.5KW Inerter, 80 350rpm |

|||

Sealing Form |

Mechanical sealing |

||||||

Reactor Lid Openings |

One Temperature measure port, installed thermometer. TC50.5*DN20 |

||||||

Reactor Lid Openings |

One liquid feeding port, TC50.5*DN20, with one ball valve |

||||||

Reactor Lid Openings |

One gas protection port, TC50.5*DN20, with one ball valve |

||||||

Reactor Lid Openings |

One gas protection port, TC50.5*DN20, with one ball valve |

||||||

Reactor Lid Openings |

One sight glass DN50 |

One sight glass DN80 |

|||||

Reactor Lid Openings |

One powder addition port DN50 |

One powder addition port DN80 |

One powder addition port DN100 |

||||

Filter Plate Material |

SUS316L |

||||||

Filter Plate Pore Size |

10um |

||||||

Discharge Port |

TC50.5*DN38 |

||||||

Reactor Working Pressure (MPa) |

-0.1-0.1MPa |

||||||

Reactor Working Temperature (C) |

-20-200°C |

||||||

Power Supply |

220V 1P |

380V 3P |

|||||

PRODUCT DESCRIPTION

YHChem YFR series stainless steel jacketed reactor (solid phase) is thecrystallization equipment after the mixed reaction of materials, the interlayerinternal demand of chilled water or refrigerant water sharply cooling, the keylink is the size of the interlayer area, the structure of the agitator and the formof material outlet, the high precision polishing in the vessel and the vesselcleaning without dead Angle requirements to meet the process conditions.Mainly used for material mixing, cooling and freezing, crystallization and so on,widely used in pharmaceutical, dairy, food, chemical, beverage and otherindustries.

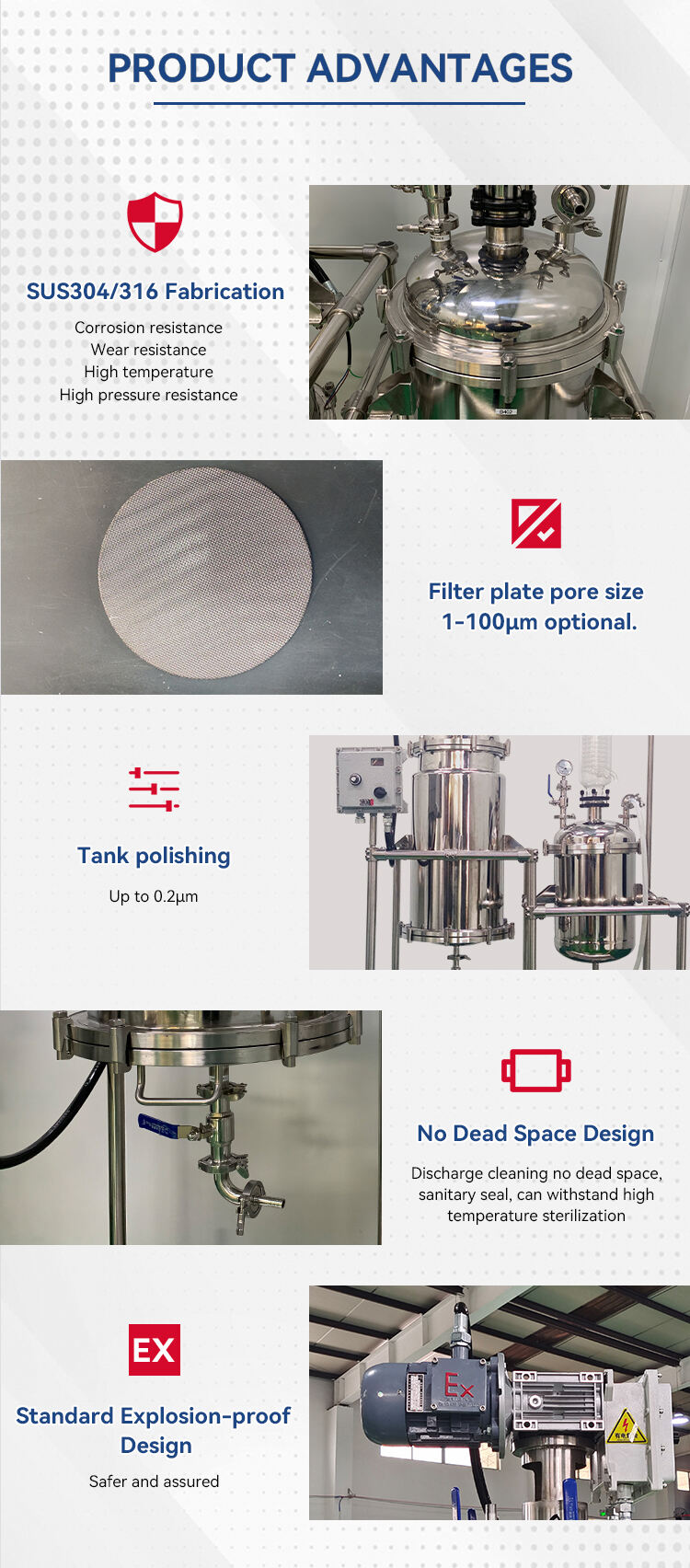

♣1.SUS304/316 Fabrication

Corrosion resistance Wear resistance High temperature High pressure resistance

♣2.Tank polishing

Up to 0.2um

♣3.Filter plate pore size 1-100um optional.

♣4.No Dead Space Design

Discharge cleaning no dead spacesanitary seal, can withstand hightemperature sterilization

♣5.Standard Explosion-proof Design

Safer and assured

♣1.Petroleum

♣2.Rubber

♣3.Chemical industryPesticide

♣4.Dye

♣5.Food

♣6.Medicine

Can be customized according to customer's requirement.

♣1.Customized kettle body

♣2.Custom glass condenser

♣3.Customized kettlelid quant

♣Motor

♣Vacuum gauge

♣Condenser

♣Solld dosing opening

♣Thermometer

♣Storage tank

♣Stainless

♣Steel filter plate

♣Discharge valve

♣304/316 stainless steel frame

♣1.Heating coolingcirculator

♣2.Stainless SteelSolid Phase Reactor

♣3.Coolingcirculator

♣4.Water cyclevacuum pump

YHCHEM, a high-tech enterprise, was established in 2009 and headquartered inShanghai with more than 50 employees both at home and abroad and an area of5,000 square meters. We have a globally competitive production base of modernbiopharmaceutical equipment, which attributes us to be a equipment and processprovider of automatic system of synthesis, extraction, separation, and purificationfor global biopharmaceutical companies With over 10-year hard work, passionand win-win spirit,YHCHEM provides more than 8,000 equipment for hundreds otwell-known companies in more than 100 countries and regions around the worldand has successfully entered Western Europe, North America and other high-levelregulatory market, and solutions are widely used in bioengineering, pharmaceuti-cal, chemical, food, environmental protection and other fields

YHCHEM

Introducing the state of the art, 10L~300L corrosion-resistant industrial scale crystallization solid-phase Stainless-steel reactor with stirring motor. This reliable and sturdy reactor is a must-have for industrial-scale processes and experiments that require precise and controlled high-quality results.

Made of high-quality corrosion-resistant Stainless-steel product that guarantees durability and longevity. It is designed by YHCHEM to withstand harsh chemicals, extreme temperatures, and tough conditions, ensuring reliable performance and usage is long-term.

Loaded with a dependable, high-speed motor is stirring provides optimal mixing and uniform heat circulation throughout the vessel. It allows for exact control of the reaction mechanism, ensuring efficiency is maximum precision in your production processes.

Suitable for a number of industrial applications, ranging from pharmaceuticals, food and beverages, chemical engineering, and more with a wide range of sizes ranging from 10L to 300L. It is built to meet all your manufacturing needs, whether you're using Bit or a scale manufacturing is large.

Easy to use, maintain, and operate. It comes with advanced features like digital temperature control, automatic force relief, and monitoring systems, ensuring user safety and efficient working conditions.

Additionally loaded with a variety of safety features that guarantee operator safety, including security valves and pressure gauges that regulate the stress and temperature inside the reactor, and prevent accidents caused by overpressure or excessive temperatures.

If you're looking for an industrial-scale reactors that provides excellent performances, accuracy, and convenience, then chooses YHCHEM. Our products are designed to meets the highest quality standards, durable and high-strength materials, and advanced technology that delivers reliable and effective performances. Ensures your success by trusting YHCHEM, a built brands on innovations, quality, and trust.

Our friendly team would love to hear from you!