Technical Specification:

Model |

YWF-1S |

YWF-2S |

YWF-3S |

YWF-5S |

YWF-10S |

YWF-20S |

YWF-50S |

Feeding rate (L/h) |

2-15 |

4-30 |

6-45 |

10-80 |

20-150 |

40-300 |

100-500 |

Evaporation area(m²) |

0.1 |

0.2 |

0.3 |

0.5 |

1 |

2 |

5 |

Condenser area(m²) |

0.3 |

0.6 |

0.9 |

1.5 |

3 |

6 |

15 |

Feeding tank volume(L) |

10 |

15 |

20 |

50 |

100 |

200 |

200 |

Minimum operating pressure(mbar) |

≤0.001 mbar |

||||||

Working temperature range(℃) |

≤300 °C |

||||||

Power supply |

220V,50/60Hz; 380V,50/60Hz(Other voltages available) |

||||||

Equipment height(cm) |

200 |

235 |

265 |

350 |

450 |

500 |

750 |

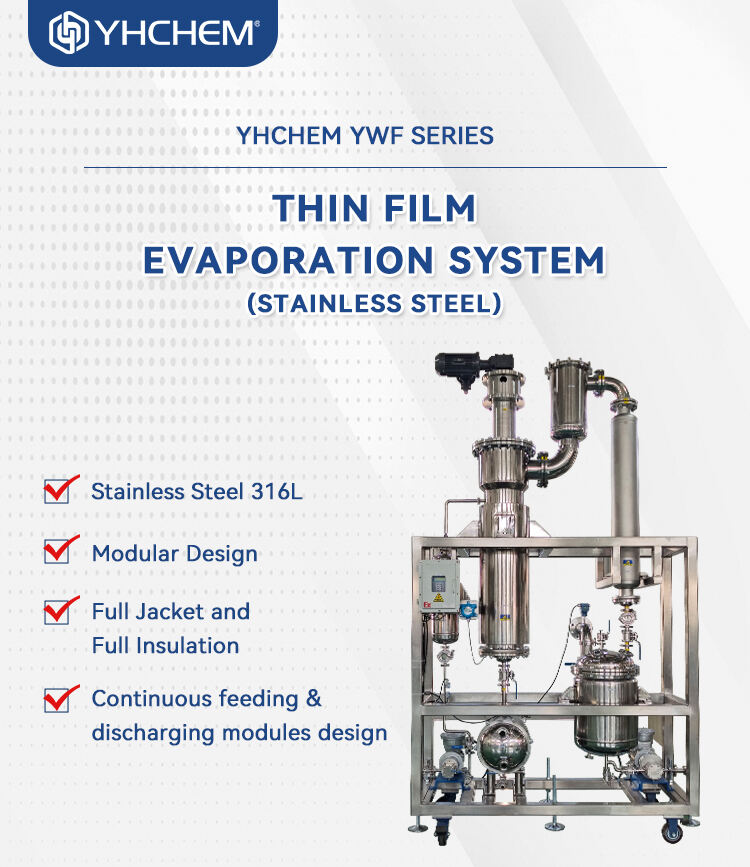

PRODUCT DESCRIPTION: YHChem YWF Series Thin Film Evaporation System(Stainless Steel) is a thinfilm distillation equipment made of stainless steel material, mainly used forseparating liquid mixtures into their components. The system mainlyconsists of a heating jacket, an internally rotatable scraper, a condenser,and a vacuum system. In the high vacuum system, the liquid material isadded tangentially to the top of the evaporator. Under the action of gravityand the rotating scraper, it forms a downward rotating thin film along theinner wall of the shell, and the liquid is discharged from the bottom outlet.The secondary steam is discharged from the top. Stainless steel thin film distillation system is widely used in industrial production for solventremoval, deodorization, and distillation separation. It an ideal choice for pilot and industrial productionequipment.

♣1.STAINLESS STEEL316L & PTFE

Good corrosion resistance, hightemperature and pressureresistance, durability,.high heattransfer efficiency, easy to clearand maintain, and capable oflong-term stable operation.

♣2.MODULAR DESIGN

Flexible options, easy main-tenance, easy scale-up, andcost reduction.

♣3.FULL JACKET ANDFULL INSULATION

Better material adaptability.

♣4.CONTINUOUS FEEDING &DISCHARGING MODULES DESIGN

lmprove production efficiency, reduceenergy costs, ensure stable product quality and reduce operational complexity.

♣5.MATCHED WITH OTHERPRODUCTS TO ACHIEVEMORE FUNCTIONS

lt is often matched withshort-path molecular distillationsystem or rectification tower toachieve more functions.

Can be customized according to customer's requirement.

♣1.FEEDING & DISCHARGING MODULES

♣2.EFFECTIVE EVAPORATION AREA

♣1.CHEMICAL INDUSTRY

it is mainly used in the preparation, separation, and refining of high-purity substances.

♣2.PHARMACEUTICAL INDUSTRY

it is mainly used in the refinement, separation and concentration of drugs.

♣3.FOOD INDUSTRY

it is mainly used in the extraction, concentration,and separation of beverages,wines, flavors, and fragrances.

♣4.BIOTECHNOLOGY

it is mainly used in the treatment of sewage and wastewater.

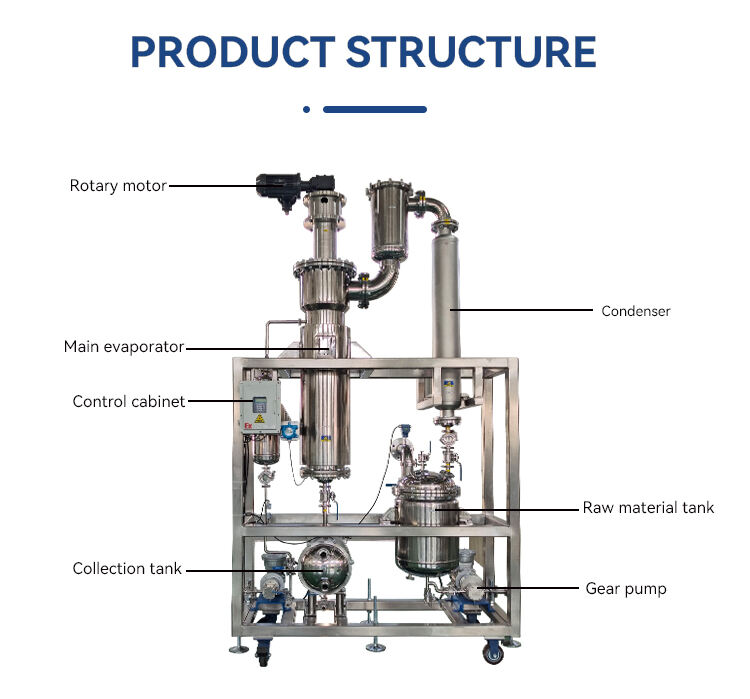

♣Rotary motor

♣Main evaporator

♣Control cabinet

♣Collection tank .

♣Condenser

♣Raw material tank

♣Gear pump

♣1.CONTROL SYSTEM

Frequency Optional automatic control system (PLC unit)

♣2.DISTILLER

YHCHEM's latest design brings betterevaporation efficiency

Optionaljacket discharge module,suitable for high boiling point viscosity materials

♣3.VACUUM SERIES

Bipolar rotary vane vacuum oil pump

Optional Roots pump Optional diffusion pump Optional molecular pump

♣4.CONSTANT TEMPERATURE SYSTEM

Heating circulator Cooling circulator Heating/cooling circulator

♣5.FEEDING & DICHARGING

Optional jacketed glass feeding tankand receiving tank (Customizable volume).

Automatic gear pump feedingand discharging system.

♣1.GJASS MOLECULAR DISTILLATION SYSTEMS(BOROSILICATE GLASS)

♣1.GJASS MOLECULAR DISTILLATION SYSTEMS(BOROSILICATE GLASS)

♣2.WIPE FILM MOLECULAR DISTILLATION SYSTEM(BOROSILICATE GLASS)

♣3.WIPE FILM MOLECULAR DISTILLATION SYSTEM (STAINLESS STEEL)

♣4.SHORT PATH DISTILLATION KIT

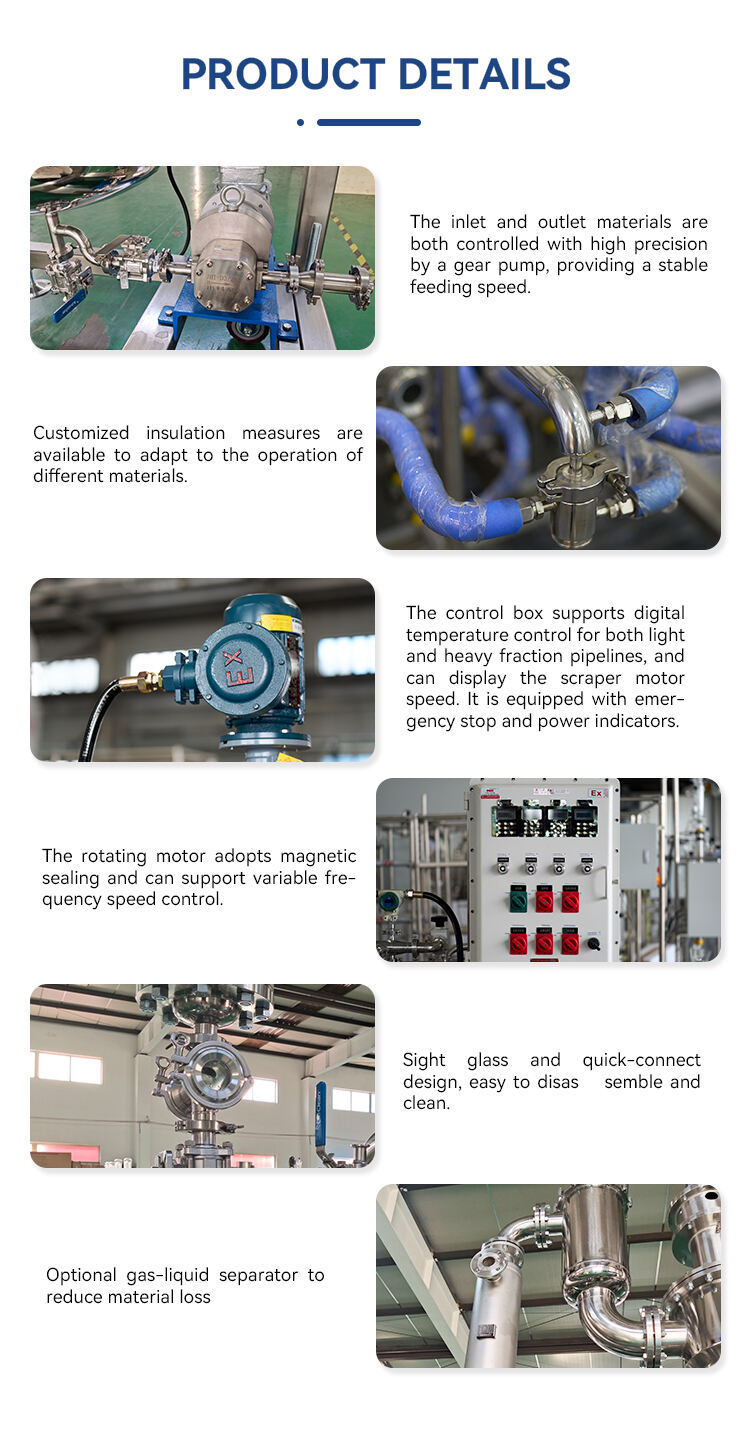

♣1.The inlet and outlet materials areboth controlled with high precisionby a gear pump,providing a stablefeeding speed.

♣2.Customized insulation measures areavailable to adapt to the operation ofdifferent materials.

♣3.The control box supports digitaltemperature control for both lightand heavy fraction pipelines, andcan display the scraper motorspeed.It is equipped with emergency stop and power indicators

♣4.The rotating motor adopts magneticsealing and can support variable frequency speed control.

♣5.Sightglass andquick-connectdesign, easy to disassemble andclean.

♣6.Optional gas-liquid separator toreduce material loss

YHCHEM, a high-tech enterprise, was established in 2009 and headquartered inShanghai with more than 50 employees both at home and abroad and an area of5,000 square meters. We have a globally competitive production base of modernbiopharmaceutical equipment, which attributes us to be a equipment and processprovider of automatic system of synthesis, extraction, separation, and purificationfor global biopharmaceutical companies With over 10-year hard work, passionand win-win spirit,YHCHEM provides more than 8,000 equipment for hundreds otwell-known companies in more than 100 countries and regions around the worldand has successfully entered Western Europe, North America and other high-levelregulatory market, and solutions are widely used in bioengineering, pharmaceuti-cal, chemical, food, environmental protection and other fields

The Full jacketed stable stainless steel thin film evaporation system distillation separation thin film evaporator from YHCHEM is an amazing piece of equipment providing you with an excellent solution distillation, especially for heat-sensitive and high-boiling point materials. This advanced method was constructed with high-quality materials and contains with accuracy to make sure that it delivers nothing but the greatest outcomes.

It features a thin film that was created from metal. The stainless metal offers durability, power, and long-lasting reliability that makes it perfect for usage in several industries including pharmaceuticals, food, and chemical processing.

Moreover, it includes a fully design jacketed that is ideal for temperature control, supplying a reliable and safe heating for heat-sensitive material. The jacketed design ensures the materials' uniform heating while preventing it from being overheated or under-heated thus, preventing thermal degradation and protecting the product quality.

It utilizes a unique process called thin-film technology, and this was driven by a rotary wiper and an adjustable speed drive motor that guarantees efficient and stable gratification. The system improves the heat transfer rate while also maintaining a uniform film layer with this technology. This leads to a fast separation, high purity, and high yield for the required product.

Furthermore, this method's compact design saves valuable flooring that makes it a great option for facilities with limited space. The Full jacketed stable stainless steel thin film evaporation system distillation separation thin film evaporator is user-friendly and simple to perform, making it the perfect option for novice. The entire device can be controlled using a central touchscreen display that shows relevant parameters such as temperature, force, and flow rate.

Our friendly team would love to hear from you!