The Thin film evaporator petrochemical distillation separation glass thin film evaporator is a petrochemical distillation separation glass thin film evaporator that offers cutting-edge technology and superior gratification. The product was made to run effectively and reliably, rendering it ideal for use within a wide number of applications.

This thin film was constructed of top-quality borosilicate glass and includes a durable, corrosion-resistant exterior which can withstand harsh surroundings. The inside of the evaporator was covered by a thin film that makes it possible for efficient separation of materials.

It is beneficial at distilling an assortment of liquids, including petrochemicals, chemical substances, and pharmaceuticals. It was meant to run at high conditions and cleaner conditions, permitting precise and efficient separation.

It features an advanced level of features, rendering it an industry-leading product. These features come with a high-reliability evaporator system, a more impressive heat range system, and an accurate movement control system. Also, this technique has a user-friendly program and easy-to-use software that enables for simple control and track of the evaporator.

It is the perfect option for petrochemical distillation separation applications along with its high level technology and superior performance. The product can be used in a wide number of applications including petrochemicals, chemical substances, and pharmaceuticals.

Additionally, the Thin film evaporator petrochemical distillation separation glass thin film evaporator was produced with both effectiveness and security in mind. It offers a security robust which include a computerized shutdown function just in case there was an urgent situation, in addition to a vacuum cleaner pump protector to stop damage to the product.

Technical Specification:

Model |

YWF-60 |

YWF-80 |

YWF-100 |

YWF-150 |

YWF-200 |

|

Feeding rate (L/h) |

0.05-3 |

0.1-6 |

0.2-10 |

0.5-15 |

0.5-20 |

|

Evaporation area(m²) |

0.06 |

0.1 |

0.15 |

0.25 |

0.35 |

|

Condenser area(m²) |

0.05 |

0.25 |

0.3 |

0.34 |

0.6 |

|

Feeding tank volume(L) |

0.5 |

1 |

2 |

2 |

5 |

|

Speed range(rpm) |

50-300 |

50-500 |

50-500 |

50-500 |

50-500 |

|

Minimum operating pressure(mbar) |

≤0.001 |

|||||

Working temperature range(℃) |

≤300℃ |

|||||

Power supply |

220V,50/60Hz; 380V,50/60Hz(Other voltages available) |

|||||

Equipment size (L/W/H, cm) |

170*61*170 |

190*61*180 |

190*61*190 |

210*61*230 |

225*60*240 |

|

YHChem YWF series Thin Film Evaporation System(Borosilicate Glass) is adevice that uses thin film technology for separation. lt mainly consists of aheating jacket, a rotatable scraper, a condenser, and a vacuum system. ln a high vacuum system, the liquid material is added tangentially to theevaporator and then driven by gravity and the rotating scraper to form adownward spiral thin film along the inner wall of the shell, and the liquid isdischarged from the bottom outlet, while the secondary steam isdischarged from the top outlet. lts advantages are suitable for highviscosity, easy crystallization, easy fouling, and suspensions orheat-sensitive materials.lt is widely used in the chemical, pharmaceutical,and health product industries,it is an ideal choice for experiment alresearch or small-scale production.

♣1.HIGH BOROSILICATE GLASS 3.3

Corrosion resistance, high temperatureresistance, and thermal shock resistanceensure the long-term stability and safetyof the system, From feeding to collectingmaterials, the entire distillation process isvisually observable.

♣2.SCRAPER FILMFORMING DESIGN

Suitable for materials with highviscosity, easy crystallization, easyfouling,containingsuspendedsolids or with thermal sensitivity.

♣3.FULL JACKETAND FULL INSULATION

To ensure material fluidity.

♣4.HIGH PRECISION ANDHIGH VACUUM DEGREE

Digital Pirani vacuum gauge ensuresprecise control, while the magneticcoupling sealmaintains highervacuum levels to ensure efficientevaporation.

♣5.EASY TO USE

It is easy to operate, use andmaintain. Users can easily adjust system parameters to meetdifferent molecular distillation requirements.

♣1.CHEMICAL INDUSTRY

it can be used for separation and purification of chemical raw materials. such as esters, aromatic hydrocarbons, aldehydes and ketones, polymers, etc.

♣2.PHARMACEUTICAL INDUSTRY

it can be used for purification and separationof drugs, such as antibiotics, hormones, vitamins, etc.

♣3.FOOD INDUSTRY

it can be used for purification and separation of food additives, flavors, pigments, etc, to improve the quality and purity of food.

♣4.BIOTECHNOLOGY

it can be used for purification and separationof biological products, such as enzymes.proteins, etc

♣5.PETROCHEMICAL INDUSTRY

it can be used for separation and purification of petrochemical products, such as naphtha, petroleum resin, polyolefins, etc.

Can be customized according to customer's requirement.

♣1.FEEDING AND DISCHARGING DESIGN

♣2.FULL JACKET

♣3.RECEIVING FLASK DESIGN

♣4.EXPLOSION-PROOF

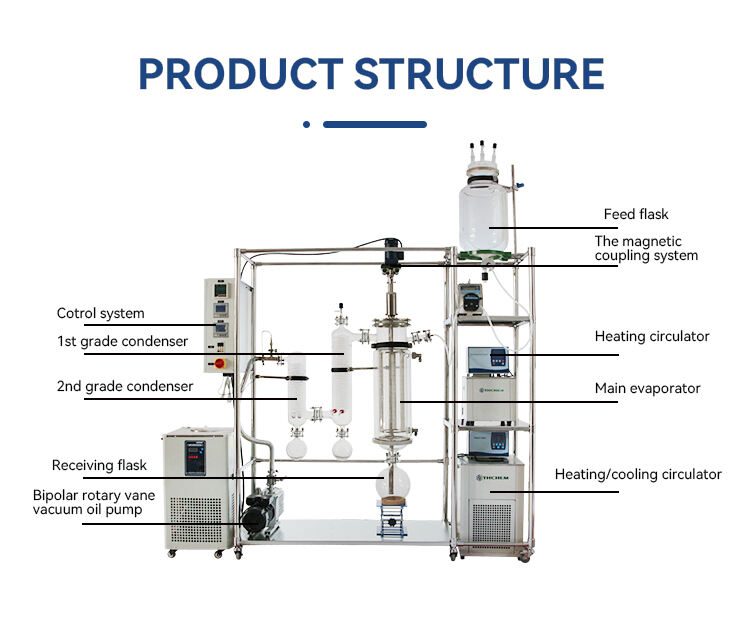

♣Feed flask

♣The magneticcoupling system

♣Cotrol system

♣1st grade condenser

♣2nd grade condenser

♣Receiving flask

♣Bipolar rotary vanevacuum oil pump

♣Heating circulator

♣Main evaporator

♣Heating/cooling circulator

♣1.CONTROL SYSTEM

Frequency Optional automatic control system (PLC unit)

♣2.DISTILLER

YHCHEM's latest design brings betterevaporation efficiency

Optionaljacket discharge module,suitable for high boiling point viscosity materials

♣3.VACUUM SERIES

Bipolar rotary vane vacuum oil pump

Optional Roots pump Optional diffusion pump Optional molecular pump

♣4.CONSTANT TEMPERATURE SYSTEM

Heating circulator Cooling circulator Heating/cooling circulator

♣5.FEEDING & DICHARGING

Optional jacketed glass feeding tankand receiving tank(Customizable volume).

Automatic gear pump feedingand discharging system.

♣1.WIPE FILM MOLECULAR DISTILLATION SYSTEM (STAINLESS STEEL)

♣2.WIPE FILM MOLECULAR DISTILLATION SYSTEM (BOROSILICATE GLASS)

♣3.THIN FILM EVAPORATION SYSTEM (STAINLESS STEEL)

♣4.SHORT PATH DISTILLATION KIT

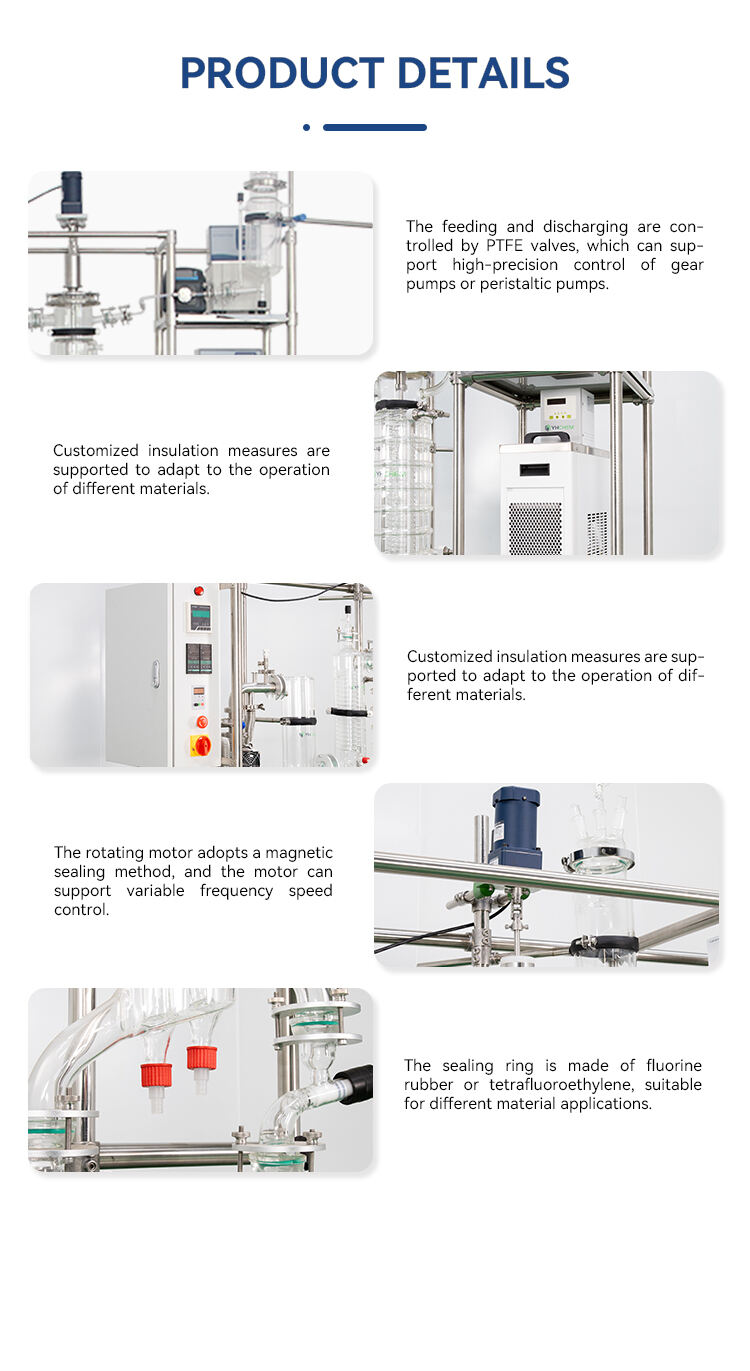

♣1.The feeding and discharging are controlled by PTFE valves. which can sup-port high-precision control ofgearpumps or peristaltic pumps.

♣2.Customized insulation measures aresupported to adapt to the operationof different materials.

♣3.The rotating motor adopts a magneticsealing method,and the motor cansupport variable frequency speedcontrol.

♣4.The sealing ring is made of fluorinerubber or tetrafluoroethylene.suitablefor different material applications.

YHCHEM, a high-tech enterprise, was established in 2009 and headquartered inShanghai with more than 50 employees both at home and abroad and an area of5,000 square meters. We have a globally competitive production base of modernbiopharmaceutical equipment, which attributes us to be a equipment and processprovider of automatic system of synthesis, extraction, separation, and purificationfor global biopharmaceutical companies With over 10-year hard work, passionand win-win spirit,YHCHEM provides more than 8,000 equipment for hundreds otwell-known companies in more than 100 countries and regions around the worldand has successfully entered Western Europe, North America and other high-levelregulatory market, and solutions are widely used in bioengineering, pharmaceuti-cal, chemical, food, environmental protection and other fields

Our friendly team would love to hear from you!