|

Model |

RE-501 |

RE-502 |

RE-503 |

RE-505 |

RE-510 |

RE-520 |

RE-530 |

RE-550 |

|

Evaporation Rate (Water L/h) poration Rate (Water L/h) |

≥1.2 |

≥1.2 |

≥2.2 |

≥2.2 |

0-3.2 |

0-5 |

0-7 |

0-9 |

|

Rotary Bottle Volume (L) |

1 |

2 |

3 |

5 |

10 |

20 |

30 |

50 |

|

Collection bottle volume (L) |

1 |

1 |

2 |

3 |

5 |

10 |

20 |

20 |

|

Heating power (W) |

2 |

2 |

2 |

3 |

3 |

3 |

5 |

5 |

|

Speed Range (rmp) |

0-180 rmp |

|||||||

|

Operating Pressure (MPa) |

-0.095 MPa |

|||||||

|

Working temperature (°C) |

RT-200 °C |

|||||||

♣1.Flexible choice forrotary flask

Inter changeable from 500m to 2000ml rotary flask

♣2. Motor liftby one button

Eliminate manual lift way, save time and man power

Lift distance: 150 mm

♣3.Double coil condenser

Large condensation area and high recovery efficiency

♣4.LCD digital display

Real-time display of data, adjustable temperature and rotation speed

♣5.PTFE & Viton seal

Strong corrosion resistance, good sealing, high vacuum degree

♣1.HIGH BOROSILICATE GLASS 3.3

♣1.HIGH BOROSILICATE GLASS 3.3

♣2.MODULAR DESIGN

♣3.STAINLESS STEEL 304

♣4.CONTINUOUS FEEDING

♣5.ANTI-SHOCK AND ANTI-CORROSION

♣6.SMOOTH OPERATION

♣1.Chemicals

♣2.Environmental Recycling

♣3.Biodiesel

♣4.Food&Beverage

♣5.Plants Extraction

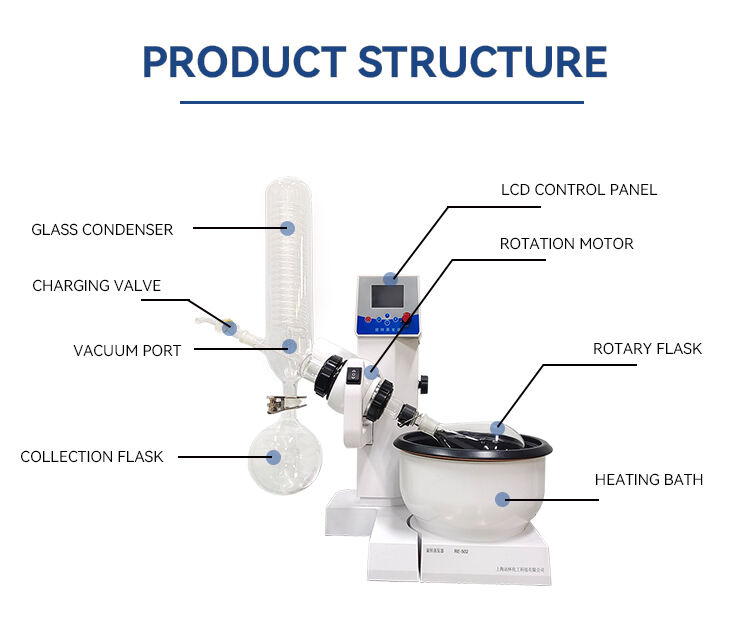

♣1.LCD CONTROL PANEL

♣2.GLASS CONDENSER

♣3.ROTATION MOTOR

♣4.CHARGING VALVE

♣5.VACUUM PORT

♣6.ROTARY FLASK

♣7.COLLECTION FLASK

♣8.HEATING BATH

♣1.Basic system

Cirulating Chiller

Vacuum Pump

♣2.Upgraded system

Vacuum Controller

Cirulating Chiller

Vacuum Pump

Our friendly team would love to hear from you!