Product Description

YRET series glass reciprocating sieve plate extraction tower is mainly composed of a reciprocating sieve plate extraction tower, light phase tank, heavy phase tank, extraction liquid tank, raffinate liquid phase tank, motor stirring system,feeding and discharging delivery pump, control system, etc. The light phase and the heavy phase enter the extraction tower from the lower part of the tower and the upper part of the tower respectively. ln the tower, the two phases come into counter-current contact. Under the action of the reciprocating sieve plate, a small droplet dispersed phase is formed . Through the counter-current contact between the dispersed phase and the continuous phase the material one or several components are selectively dissolved in a continuous solvent for mass transfer.

Product Parameter

| Model | YRET-25 |

| Material | High borosilicate 3.3 |

| Processing capacity | 30L/h |

| Extraction tower diameter | 25mm |

| Extraction effective height | 1500mm |

| Light phase tank | 10L |

| Heavy phase tank | 10L |

| Collection bottle | 10L |

| Raffinate tank | 10L |

| Buffer tank | 2l*2 |

| Speed regulating motor and Reducer | 370w |

| Feed pump (optional) | Peristaltic pump*2 |

| Dimension | 900*800*3700mm |

| Weight | 55kg |

♣1.CONTINUOUS PRODUCTION

The extraction tower adopts a continuous production method, allowing for stable and continuous operation, which enhances both production efficiency and product quality.

♣2.SMALL FOOTPRINT LARGE PROCESSING CAPACITY LOW SOLVENT USAGE

Due to its unique structural design, the extraction tower has a relatively small footprint, enabling large-scale processing in limited spaces, thus improving production efficiency. Additionally, this extraction tower uses a relatively small amount of solvent, reducing production costs while also being more environmentally friendly.

♣3.LOW PRESSURE DROP HIGH MASS TRANSFER EFFICIENCY

The extraction tower features a low pressure drop, which reduces the energy consumption and wear of the equipment, thereby extending its service life. lt has high mass transfer efficiency, enabling efficient material transfer and separation,which

improves the quality and purity of the products.

♣4.SUPPORT CUSTOMIZED SERVICES

lt can be customized according to client requirements. The materials are generally divided into high borosilicate glass,304 stainless steel, 316L stainless steel, titanium alloy, etc. The number, spacing and other structures of the sieve plates can be calculated and provided based on the performance of the material and the required degree of separation and purity.

Three operating modes are available: fully automatic semi-automatic, and manual operation.

YRET series glass reciprocating sieve plate extraction towers are widely used in the separation and purification of liquid mixtures, and are widely used in fermentation , bioengineering , fine chemicals, etc.

♣1.FERMENTATION

♣2.BIOENGINEERING

♣3.FINE CHEMICALS

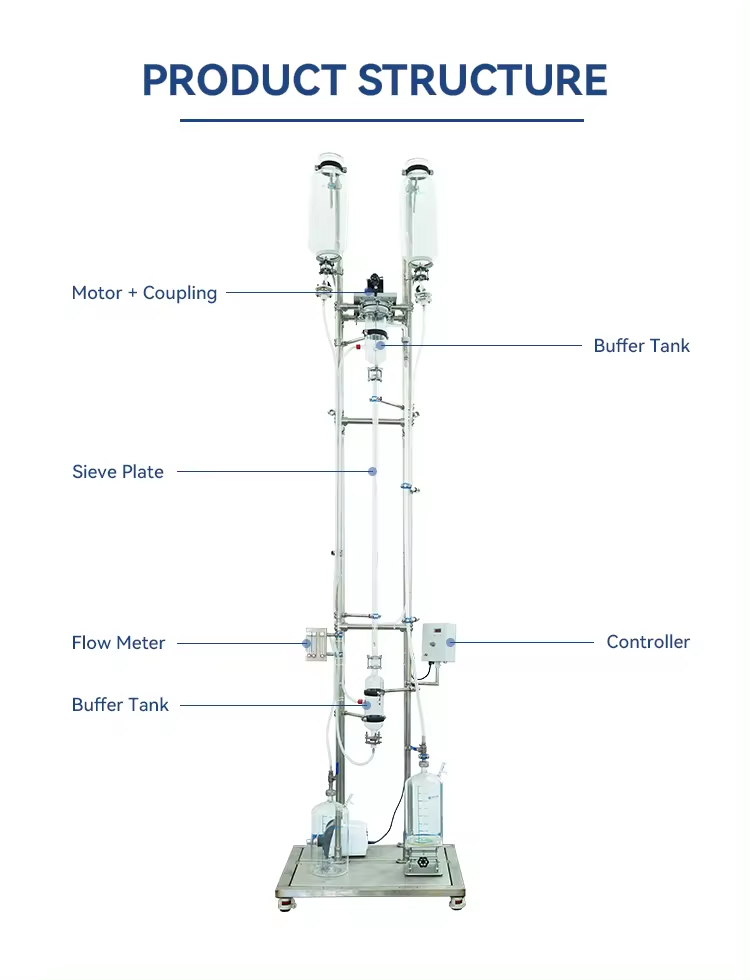

♣Motor + Coupling

♣Buffer Tank

♣Sieve Plate

♣Flow Meter

♣Controller

♣Buffer Tank

♣PERISTALTIC PUMP

♣PERISTALTIC PUMP

♦♦Q&A

••Q: What is the difference between extraction tower and distillation tower ?

••A: The distillation tower separates substances based on the principle of distillation, that is, using the difference in boiling point of each component in the mixture to sublimate some of the components under the action of heating, and then condense to recover a single component. The extraction tower separates substances based on the extraction principle, that is, using two or more immiscible solvents to extract the mixture to achieve separation of substances, which is separated through differences in

solubility.

The distillation tower can separate components with different boiling points in the mixture through continuous vapor-liquid equilibrium separation.The extraction tower can use the absorbent to contact the mixture in counter current to absorb the target components and achieve liquid-liquid material separation.

••Q: What are the advantages of an extraction tower comparedto a distillation tower?

••A: There are obvious differences between the distillation tower and the extractiontower in terms of operating principles and application scenarios, but they both have efficient separation effects. The specific choice of which equipment to use needs to be determined based on the actual process requirements and material characteristics.

Our friendly team would love to hear from you!