YHChem YFE Series Falling Film Evaporator is an evaporator that utilizes liquid film to flow and evaporate on the heating surface. lt is an efficient heat transfer device that is suitable for processing high-concentration organic compounds, high-salinity aqueous solutions, high-viscosity liquids, and so on. The falling film evaporator introduces the feed liquid into the heat exchanger of the falling film evaporator, and after the liquid distribution and film-forming device, itis evenly distributed into each heat exchange tube. Under the action of gravity, vacuum induction, and air flow, the liquid flows downward uniformly in a film shape. During the flow, the heating medium in the shell side heats up and vaporizes, and the vapor and liquid phasesenter the separation chamber of the evaporator together. After sufficient separation, the vapor enters the condenser for condensation and collection. The falling film evaporator is mainly used in the solvent recovery of the biological, pharmaceutical, and chemical industries, andcan be used in multiple stages to achieve higher energy efficiency ratio.

| Model | YFE-50 | YFE-100 | YFE-200 | YFE-300 |

| Ethanol Evaporation Rate(L/h ) | 90 | 180 | 350 | 500 |

| Evaporation Area (㎡) | 3.5 | 6 | 11.5 | 15 |

| Condensation Area (㎡) | 6 | 15 | 23 | 33 |

| Evaporator design pressure (MPa) | -0.098 | |||

| Volume of Class I recovery tank (L) | 25 | 55 | 105 | 150 |

| Volume of Class II recovery tank (L) | 25 | 55 | 105 | 150 |

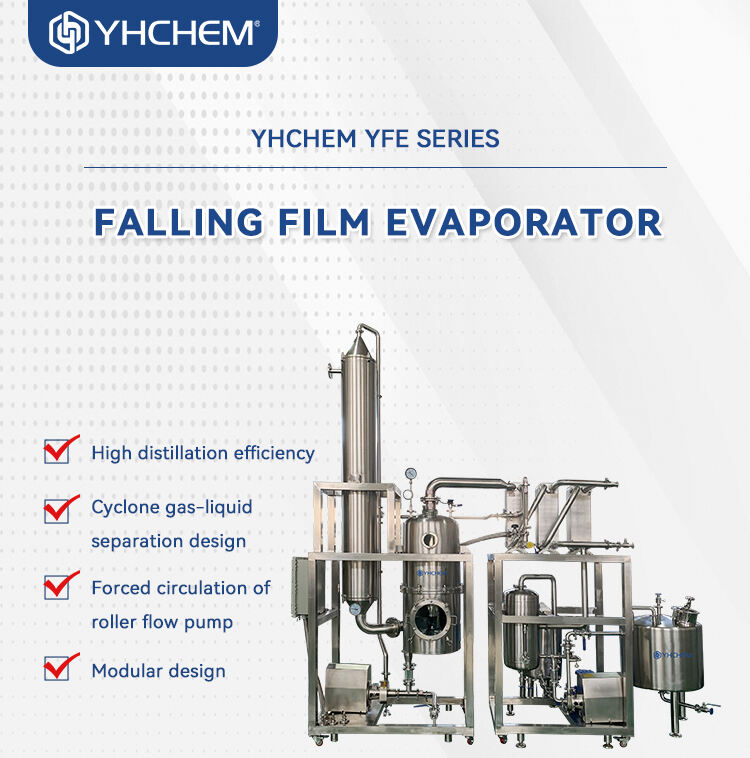

♣1.GOOD EVAPORATIONEFFECT

As the material is always kept in a thin film state during the falling film process and heated uniformly, it can evaporate quickly with high heat transfer efficiency. This avoids problems such as local crystallization and sintering that may occur due touneven heating in traditional evaporation processes.

♣2.MODULAR DESIGN

Flexible replacement orupgrade of configuration components, compact structure, and convenient disassembly and maintenance to reduce costs.

♣3.CYCLONE GAS-LIQUIDSEPARATION DESIGN

reduces material loss, lmprove separation efficiency, reduce energy consumption,increase operational safety, and facilitate maintenance

and cleaning

♣4.FORCED CIRCULATION OFROLLER FLOW PUMP

increase material concentration increase ensure uniform liquid film, prevent scaling, enhance operational stability and increase heat transfer efficiency

♣5.THE ULTIMATE VACUUMIS LOWER THAN 50MBAR

Which is good to reduce energy consumption

Can be customized according to customer's requirement. ♣1.GLASS FALLING FILM DESIGN

♣2.CUSTOMIZED DESIGN FORHEAT TRANSFER AREA

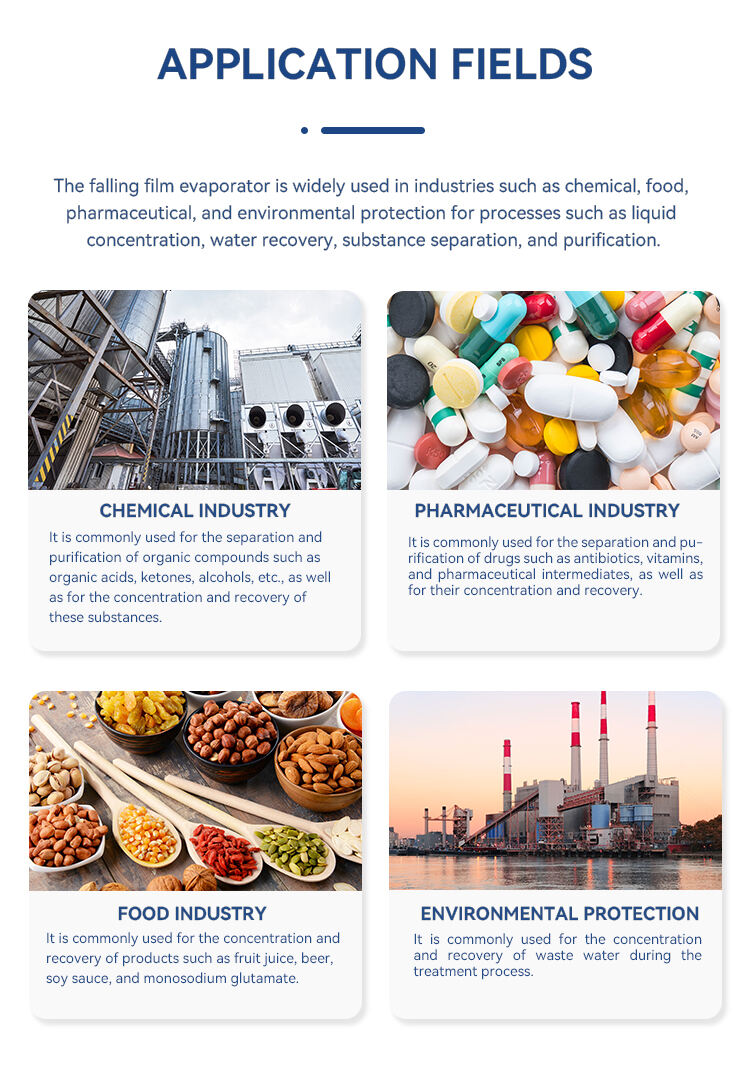

♣1.The falling film evaporator is widely used in industries such as chemical, food and environmental protection for processes such as liquid concentration, water recovery, substance separation, and purification.

♣2.CHEMICAL INDUSTRY

It is commonly used for the separation and purification of organic compounds such asorganic acids, ketones, alcohols, etc. as well as for the concentration and recovery of these substances.

♣3.It is commonly used for the separation, purification, concentration and recovery of antibiotics, vitamins, etc.

♣4.FOOD INDUSTRY

lt is commonly used for the concentration and recovery of products such as fruit juice, beer, soy sauce and monosodium glutamate.

♣5.ENVIRONMENTAL PROTECTION

It is commonly used for the concentration and recovery of waste water during the treatment process

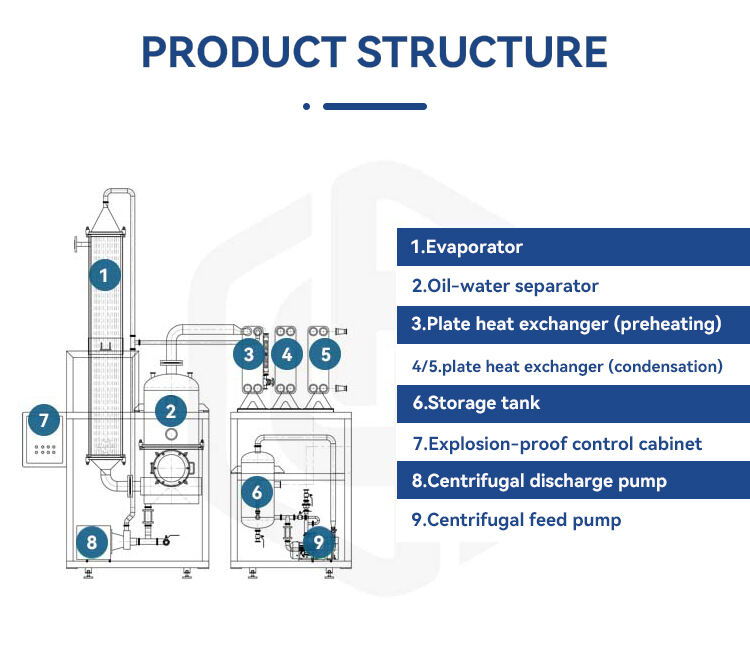

♣1.Evaporator

♣2.Oil-water separator

♣3.Plate heat exchanger (preheating)

♣4/5.plate heat exchanger (condensation)

♣6.Storage tank

♣7.Explosion-proof control cabinet

♣8.Centrifugal discharge pump

♣9.Centrifugal feed pump

♣1.Cooling circulator

♣2.Heating circulator

♣3.The rotary vane vacuum pump ♣1.WIPE FILM MOLECULAR DISTILLATION SYSTEM (STAINLESS STEEL)

♣1.WIPE FILM MOLECULAR DISTILLATION SYSTEM (STAINLESS STEEL)

♣2.WIPE FILM MOLECULAR DISTILLATION SYSTEM (BOROSILICATE GLASS)

♣3.THIN FILM EVAPORATION SYSTEM (STAINLESS STEEL)

♣4.THIN FILM EVAPORATION SYSTEM (BOROSILICATE GLASS)

Our friendly team would love to hear from you!