Sugar substances are widely used in industries such as daily chemicals and brewing. Today, various sweeteners or sugar substitutes (like erythritol and stevia) are becoming increasingly popular. However, traditional extraction processes have numerous...

Share

Sugar substances are widely used in industries such as daily chemicals and brewing. Today, various sweeteners or sugar substitutes (like erythritol and stevia) are becoming increasingly popular. However, traditional extraction processes have numerous issues, such as long production times and the need to add preservatives. The solution provided by Yuanhuai can effectively address these pain points for users.

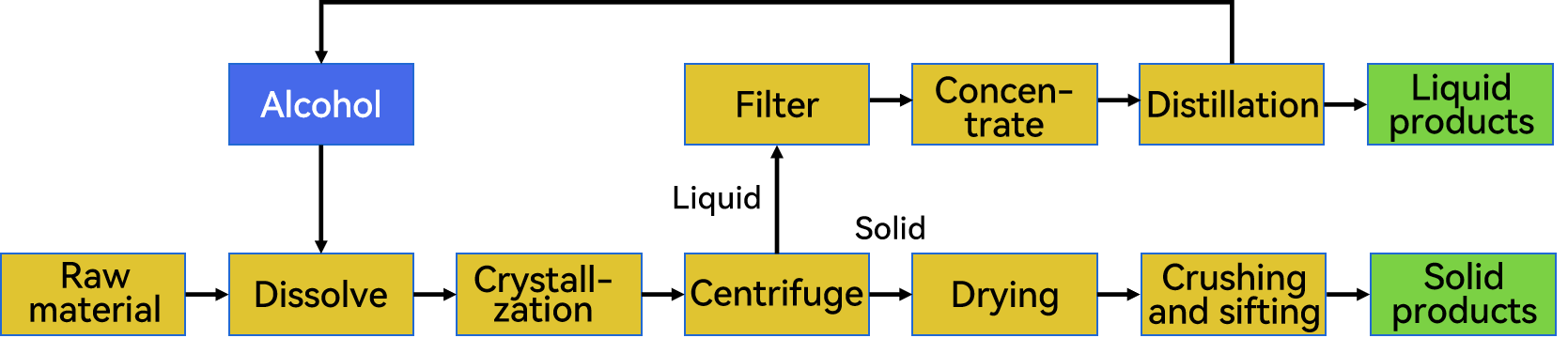

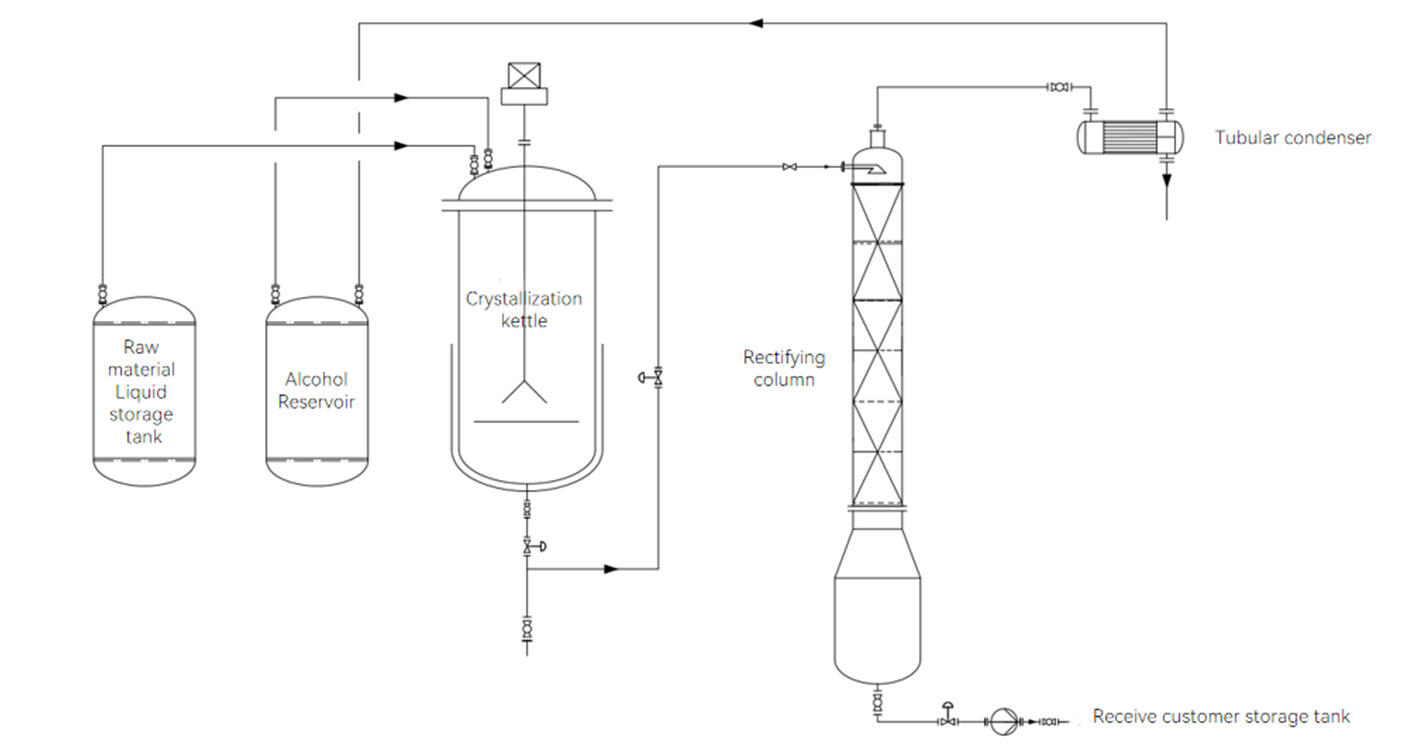

In the complete solution, the initially processed crude material is dissolved in a crystallization tank using a solvent (such as ethanol), from which the crystals are precipitated. These are then separated using a centrifuge. The liquid material with a high sugar content undergoes further purification in a rectifying column, yielding a sugar solution, with the solvent being fully recovered and reused in the process. The high-purity sugar crystals are dried in a vacuum drying oven, crushed, and then sieved to obtain the solid product directly.