TCU Temperature Control System, Excellent Performance for Precise Temperature Control

The TCU Temperature Control System, designed by Yuanhuai, is a specialized device for precise temperature control in the chemical and pharmaceutical industries. It is used for heating, cooling, constant temperature, distillation, and crystallization processes in batch reactors or continuous process operations. It is particularly suitable for process control involving heat transfer and heat release during reaction processes.

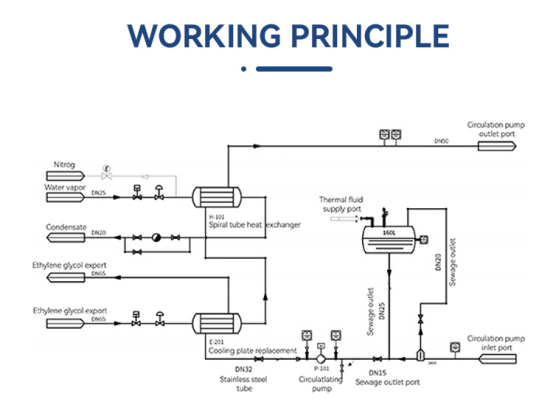

This system integrates highly efficient heat exchangers, circulating pumps, thermometers, pressure gauges, various sensors, pipelines, valves, and automatic control systems into a complete set of high and low-temperature heating/cooling control system equipment. It also features an automatic pressure relief control system, which combines the selection of centrifugal pumps, valves, pipeline flange welding, and on-site installation and commissioning of electrical controls.

Advanced Temperature Monitoring and Regulation

The TCU Temperature Control System utilizes precise sensor technology and intelligent control algorithms to monitor and regulate temperature in real time. Users can achieve a closed-loop, repeatable temperature control within a wide temperature range. The specially designed device can operate in a temperature range of -20°C to +300°C. Whether in high-temperature or low-temperature environments, the system can stably maintain the temperature of equipment, laboratories, or process operations within the predetermined range.

Intelligent Control and Optimization

Our TCU system features intelligent control capabilities. Using the feedback temperature as a signal source, the controller calculates and provides instructions for the electric actuator's movements. It controls the flow of low-temperature liquid into the reactor jacket, achieving efficient control. Through rapid calculations, the system controls the temperature of the entire reaction process, allowing for quick response control during exothermic and endothermic reactions. Users can choose to control the temperature of the reaction process and the temperature of a single fluid, and the temperature difference between the reaction process and the heat transfer fluid can be set and controlled.

More Rational Design

The system adopts a fully sealed pipeline design, enabling recipe management and process recording. It incorporates various coiled heat exchangers made of stainless steel, which are corrosion-resistant, high-pressure resistant, and scale-resistant, ensuring high heat transfer efficiency. It eliminates the need for traditional equipment replacement and jacket maintenance. The system also includes a built-in electric heating and heat transfer oil auxiliary system, which automatically activates the auxiliary heating system according to demand, reducing steam usage pressure. By accurately proportioning the heat requirements through fast operation, energy savings can be achieved. The system provides standardized interfaces, allowing for the addition of cold and heat source heat transfer modules according to actual needs.

Versatile Applications

The Yuanhuai TCU Temperature Control System is widely applicable in fields such as chemical, pharmaceutical, food, biotechnology, new materials, and petrochemical industries. Our system provides personalized temperature control solutions to meet the specific requirements of different industries.

User-Friendly Operation

We prioritize user experience and have designed a simple and easy-to-use interface. The Yuanhuai TCU Temperature Control System is equipped with an intuitive control panel, allowing users to easily set temperature parameters and monitor temperatures.

Technical Specifications.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN