YHCHEM d Gumagamit ng isang unikong panloob na estraktura ang disk microreactor upang makabuo ng mabilis na tulak-tulak na pamumuhunan ng panloob na mga anyo, na maaaring mapabuti ang paghalo ng likido, mapataas ang pagsisiyasat ng masa at init, at maaaring gamitin para sa mga reaksyon na may higit na fase at reaksyon sa ilalim ng mataas na panganib o malubhang kondisyon. Ayon sa iba't ibang sitwasyon, inilalapat ang serbisyo ng custom-made one-stop na may layunin na pigilan ang oras ng reaksyon, bawasan ang pagkakahubad ng yaman, mapabuti ang kalidad at kalinisan ng produkto,alisin ang panganib sa seguridad, bawasan ang polusyon sa kapaligiran, at maabot ang walang katapusan na paglaki mula sa laboratorio hanggang sa industriyal na produksyon.

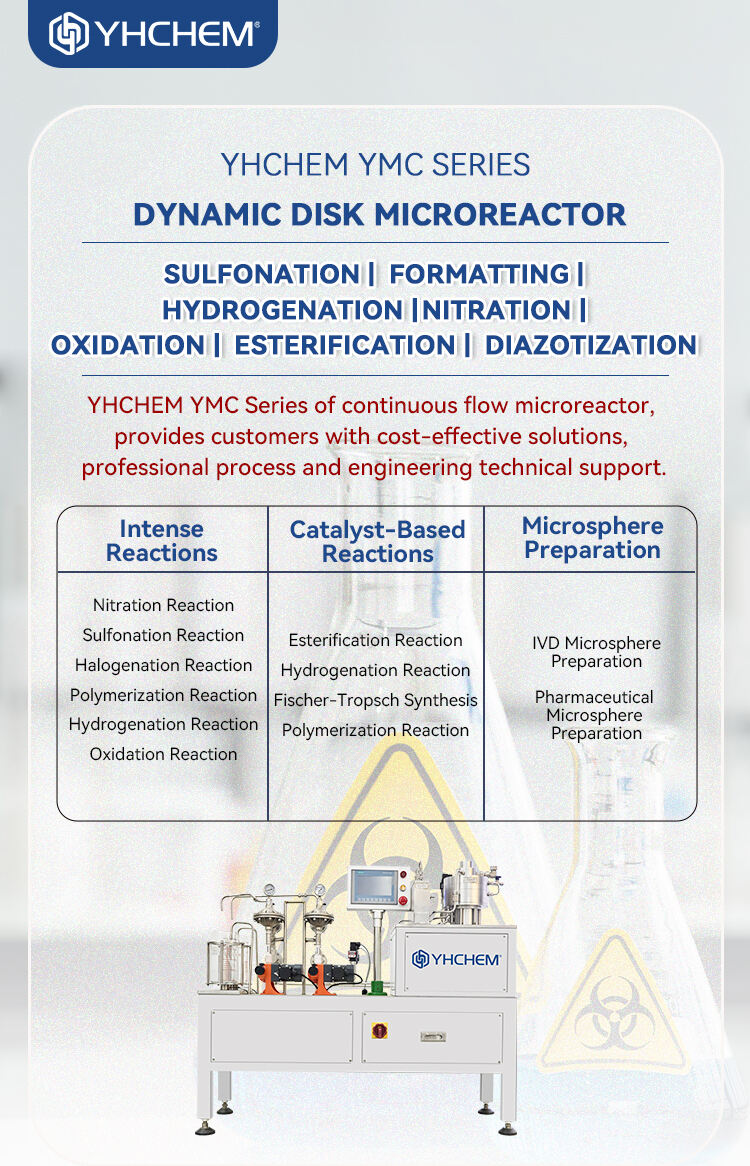

Malawak na Saklaw ng mga Aplikasyon

Parmaseytikal na mga tagahawak, sintesis ng gamot, maikling kimika, ahaskimika, espesyal na kimika, industriya ng pang-araw-araw na pangangailangan, nanomaterials, farmasetiko, polymer modification, etc.

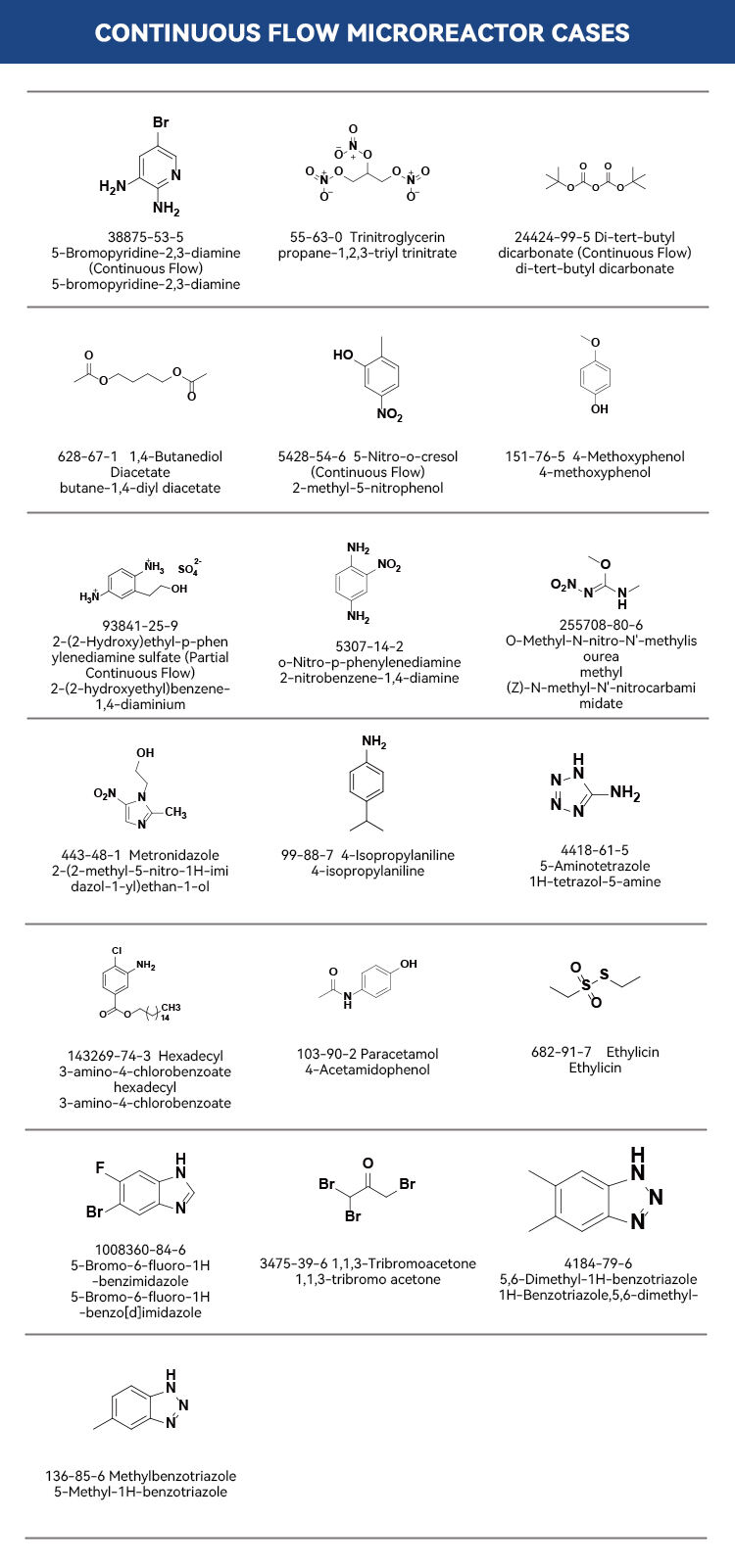

Maaaring isagawa ang mga karaniwang reaksyon tulad ng pag-nitrate, sulphonation, diazotisation, oksidasyon, peroxidation, hydrogenation, chlorination, fluorination, halogenation, polymerisation, cyclisation, isomerisation, esterification, amination, alkylation, hydroxylation, acid-base neutralisation, etc. gamit ang microreactor.

Mga karakteristikong proseso

Matinong kontrol ng temperatura ng reaksyon at oras ng reaksyon, mabilis at ligtas na proseso ng reaksyon, malaking espesyal na sipa, homonyum na paghalo ng mga materyales, pag-iipon ng enerhiya at pagbabawas ng emisyon, kompaktong anyo, walang epekto ng paglaki.

● Maliit ang sukat ng kagamitan para sa reaksyon, mabilis na paghalo ng mga materyales, epektibidad ng pagsisiyasat at pagpapalipat-ng-init, madaling maabot ang proseso ng pagsusulong. .

● Ang distribusyon ng panahon ng pagsasakay ay maiikli, mabilis na tumugon ang sistema, mabuting repetibilidad ng proseso, ligtas ang kalidad ng produkto. .

● Ang kontrol ng parameter ay tiyak (kabilang ang paghahati ng konsentrasyon, paghahati ng temperatura at paghahati ng presyon, mga iba pa), madali ang automatikong kontrol .

● Halos walang epekto ng amplifikasiyon, maaaring ma-scale up nang mabilis .

● Mababang halaga ng materyales online, angkop para sa hindi pangkaraniwang kondisyon ng reaksyon (hal. mataas na temperatura at presyon), intrinsikong ligtas na proseso; tuloy-tuloy na operasyon, mataas na efisiensiya ng espasyo-panahon, taubos ng kapwa.

Ayon sa estadistika, halos 18.5% ng mga proseso ng reaksyon sa sintesis ng kemikal na gamot ay maaaring optimisahan at mapabuti sa aspeto ng pagsisingil, produktibidad ng espasyo-panahon, seguridad at ekonomiya sa pamamagitan ng teknolohiyang tuloy-tuloy na mikroreaksiyon.

Mga Tampok ng Produkto

● Mataas na estraktura ng shear sa loob, mabilis na iguhit na impelyer para sa pag-uugnay upang siguraduhin ang regular na materyales, mataas na estabilidad ng produkto.

● Angkop para sa mga reaksyon na may natutunghay o nabubuo na likido na materyales, solid phase, at maaaring idagdag ang suspension materials.

● Mataas na ekad ng pag-mix, maaaring bumuo ng mikro at nano partikula, pagsisigla ng reaksyon, prevensyon ng blokeho.

Mga teknikal na pakinabang

● Mataas na ekad ng transfer ng masa at init, mataas na epekto ng pag-mix

● Precise na kontrol ng proseso, in-line inspeksyon, modularidad, awtomasyon

● Bawas na side effects, disenyo ng kanal na may laki ng micron

● Maliit na volumeng pagsagot at maliit na kapasidad ng likido

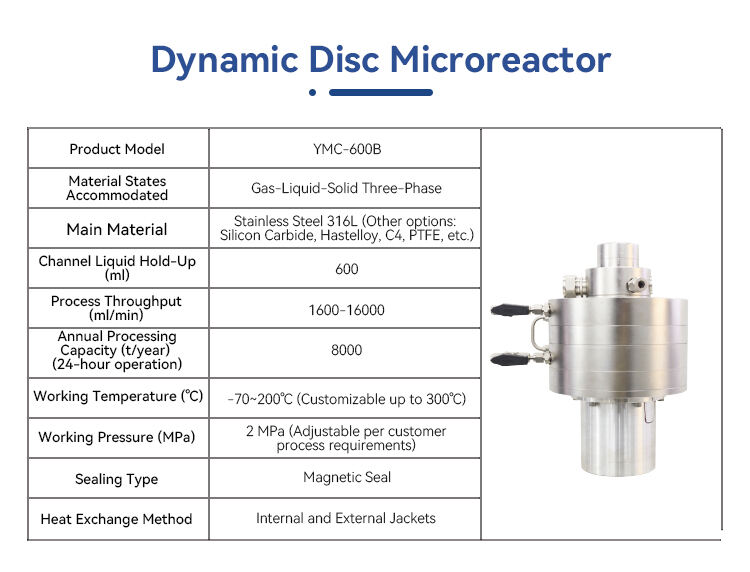

● Pinakamataas na resistensya sa presyon 40MPa, resistensya sa korosyon (silicon carbide/Hastelloy)

● Mababang paggamit ng enerhiya at mababang paggamit ng katalista

● Maiiwasang mga sakuna, mababang kapasidad ng likido

● Maiiwasang epekto ng paglago, mabilis na pagpapatunay ng proseso

● Resistente sa mataas na temperatura, diversipikadong mga material (316L/Hastelloy, etc.)

● Mahabang buhay ng catalyst at mataas na katatagan ng sistema

User Value

● Mataas na produktong yield at mataas na ekwidensiya ng produksyon

● Maikling siklo ng produksyon at mabilis na paglago ng produksyon

● Mataas na kalinisan ng produkto at pagsisisi

● Maliit na footprint at intrinsic na ligtas

● Pag-adapt sa mga peligroso na proseso tulad ng nitrification\/chlorination

● Mababang integradong pagsasanay at mababang gastos ng paggamit

● Paggayang pangkapaligiran at mababang panganib ng seguridad

● Mabilis na industrialisasyon at binawasan na mga gastos ng R&D

● Nagkakasalungat sa mga farmaseutikal/electronikong kimika, mga iba pa.

● Paghahanda ng maagang pag-optimize ng gastos sa operasyon