- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

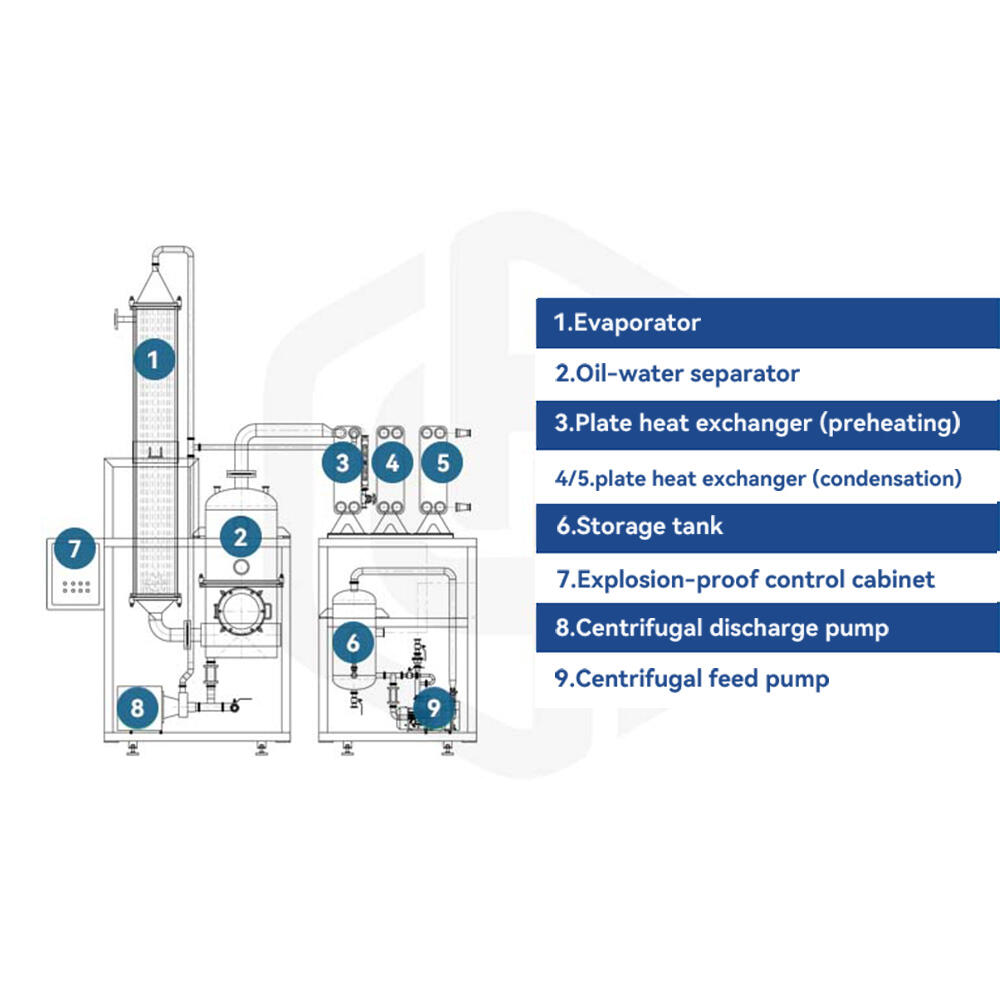

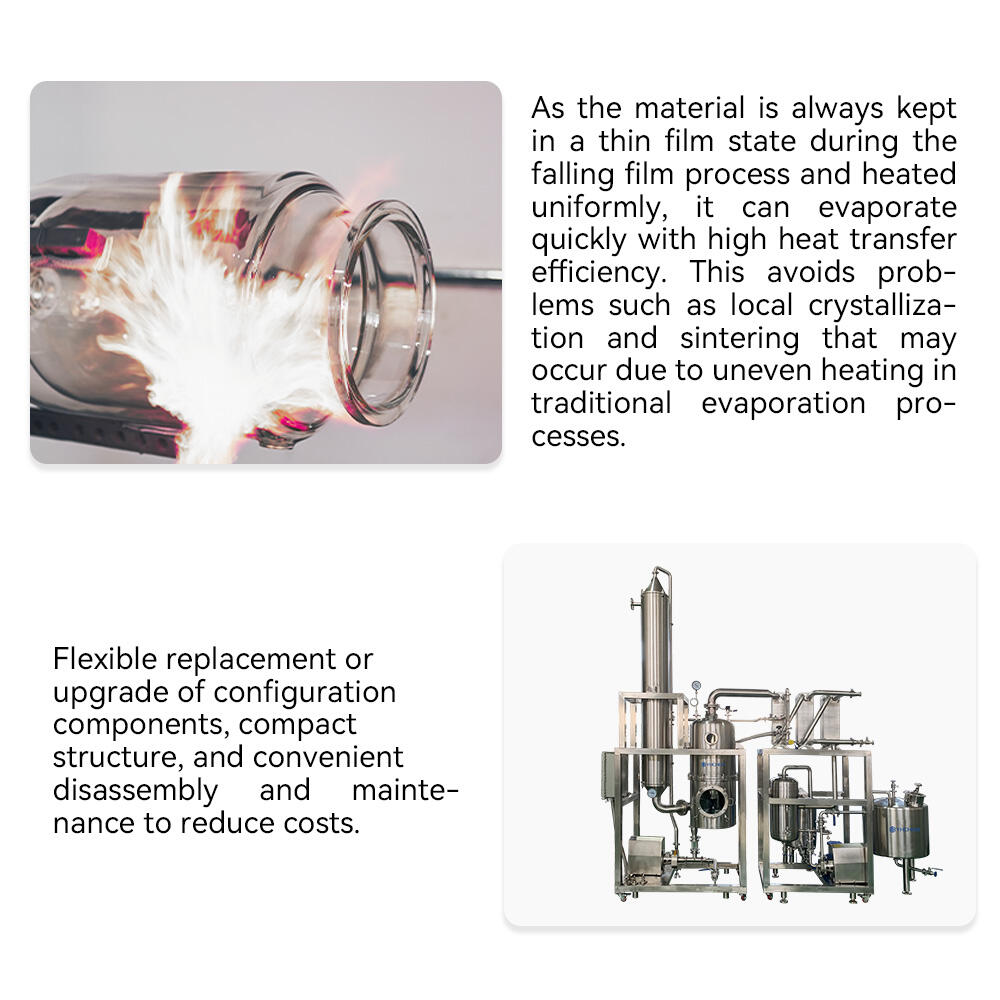

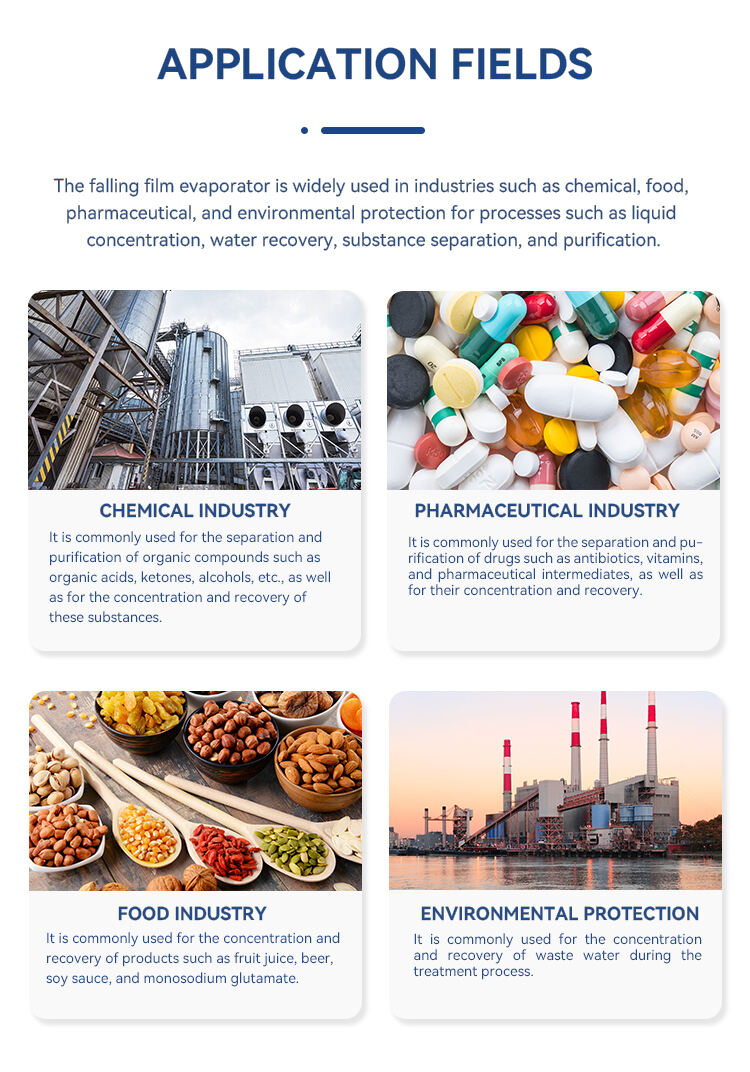

The solvent recovery unit is to add the liquid from the heat exchanger, through the liquid distribution and film forming device, evenly distributed into each heat exchange tube, under the action of gravity, vacuum induction and air flow, it becomes a uniform film flow down from the top. During the flow process, it is heated and vaporized by the heating medium in the shell side, and the generated vapor and liquid phase enter the separation chamber of the evaporator together. After the vapor-liquid is fully separated, the vapor enters the condenser to be condensed and collected. The solvent recovery units are mainly used in solvent recovery in biological, pharmaceutical, chemical and other industries, and can be used in multiple stages to achieve a higher energy efficiency ratio.Especially suitable for thermosensitive materials, it can operate continuously in a vacuum low-temperature environment, with high evaporation capacity, energy saving, low operating costs, and ensures material integrity during the evaporation process.

Features

● Modular design, flexible configuration

● Continuous feeding and discharging design, saving labor costs and operation time

● Complete set design for wider material adaptability

● Magnetic coupling seal can maintain higher vacuum degree, ensuring evaporation effect

● 316L stainless steel material, high heat transfer efficiency, safe and reliable

● With sight glass and quick connection design, convenient disassembly and cleaning

● Optional gas-liquid separator to reduce material loss

● Can be paired with short-range molecular distillation systems or distillation towers for more functions

● Continuous feeding and discharging design, saving labor costs and operation time

● Complete set design for wider material adaptability

● Magnetic coupling seal can maintain higher vacuum degree, ensuring evaporation effect

● 316L stainless steel material, high heat transfer efficiency, safe and reliable

● With sight glass and quick connection design, convenient disassembly and cleaning

● Optional gas-liquid separator to reduce material loss

● Can be paired with short-range molecular distillation systems or distillation towers for more functions

Typical Applications

Fine chemicals, biopharmaceuticals, food and agriculture, new materials, petrochemicals, fragrances, and flavors, etc

Product Parameter

| Model | YFE-50 | YFE-100 | YFE-200 | YFE-300 |

| Ethanol Evaporation Rate(L/h ) | 90 | 180 | 350 | 500 |

| Evaporation Area (㎡) | 3.5 | 6 | 11.5 | 15 |

| Condensation Area (㎡) | 6 | 15 | 23 | 33 |

| Evaporator design pressure (MPa) | -0.098 | |||

| Volume of Class I recovery tank (L) | 25 | 55 | 105 | 150 |

| Volume of Class II recovery tank (L) | 25 | 55 | 105 | 150 |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN