YHCHEM прапаноўвае розныя рашэнні, такія як дыстыляцыя і адчыненне, каб дасягнуць чысценькасці рыбнага масла ў розных чысценнінах. Пазадніцца: Глыбакамарскія рыбныя масла — гэта тып натуральных здароў'явых працэдураў з вышэйшай харчавальнай чысценнінаю, багатае поліненасыщаным жырным...

Дзяліцца

YHCHEM прапануе розныя рашэнні, такія як дыстыляцыя і рафінацыя, для дасягнення чысценькары рыбнага маўла ў розных ступенях чыстата.

Кантэксц:

Масло глыбінавых рыбаў — гэта від натуралійнага здравапазнальнага працюку з вышынайным харчовым значэннем, багатае поліненасыщанымі жырнымі кіслотамі, у тым ліку кіслотамі омега-3, такімі як эйкозапентаенавая кіслата (EPA) і дакозагексаенаевая кіслата (DHA). Сучасныя медыкальныя даследаванні паказваюць, што EPA і DHA маюць ключавыя фізіалагічныя функцыі, такія як зніжэнне кроўных ліпідаў і халестерыну, супрацоўнічаюць ў розвіцці мозгавых нерваў і сітчаткі, маюць антыэпілептычныя і антыарытмічныя ўплывы, а таксама палягаюць у прафілацыйце склератызацыі кроўных суднаў. Яны можуцьэффектыўна захаваць і карыстаць пэўныя хворобы, такія як артыяльная гіпертанзія, серцаўныя хворобы, рак і цукровы дыябет. У сучаснасці шырока выкарыстоўваюцца экстракцыі, якія выконваюцца метадам халоднага кристалізавання і уреавых ўключэнняў, якія маюць недастаткі: нізкія ступені экстракцыі і праблемы з залишкам салінтавання. YHCHEM прапануе розныя рашэнні, такія як дыстыляцыя і рафінацыя, для дасягнення чысценькары рыбнага маўла ў розных ступенях чыстата.

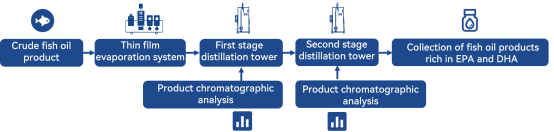

Працэс выработкі рыбнага масла:

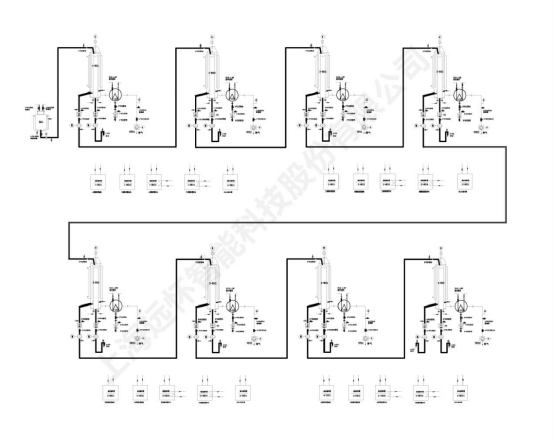

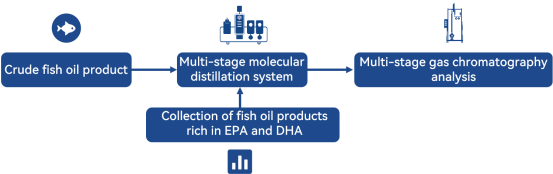

У гэтым процесе як кормовая матэрыял выкарыстоўваецца сыр'ёвы рыбны мас, і апарат для молекулярнай дыстыляцыі адпавядна дапрацоўваецца з улікам ўтварэння складнікаў і колькасці корма. Праз многаступенчатую молекулярную дыстыляцыю паслядоўна выдаляюцца лёгкія нячыстыя складнікі. З тым как збяльшэнне колькасці ступеней молекулярнай дыстыляцыі, збяльшаецца ўтварэнне EPA ў лёгкай фазе і ўтварэнне DHA ў цяжкай фазе да тех пагод, покуль не будзе дасягнутая мэтная канцэнтрацыя, пасля чаго збіраюцца продукты лёгкай і цяжкай фаз. Падчас карыстання настройкай працэсу, для рэалізма аналізу і знайдзення ўтварэння рыбнага масла выкарыстоўваецца газавая хроматографія, каб забяспечыць якасць працэсу.

У гэтым працэсе выкарыстоўваецца нефармаўанае рыбнае масяж як кормавая матэрыяла, і адпаведная дапрацоўка робіцца на аснове зместу і колькасці кормавых кампанент. Устройства цінкага фільма ўпарвання вылічваюць лёгкія кампаненты з колькасцю углеродных атамаў менш за 18, і тяжкае фаза ўвайшла ў першую башню дыстыляцыі для прадалжэння ўдалення кампанентаў з короткімі цепкамі карбонаў з нізкім зместам. Першая башня дыстыляцыі аддзеліла тяжкае фаза, багата EPA і DHA нясытымі жырнымі касцідамі, якія потым падлягаюць рэал-часаваму і дакладному маніторынгу чыстасці з выкарыстаннем газавай хроматаграфіі. Пасля гэтага тяжкае фаза з першай ступені дыстыляцыі ўвайшла ў другую ступень дыстыляцыі, дзе EPA і DHA аддзеляюцца па працэсных патрабаваннях. Выходы лёгкіх і тяжкіх фаз аналіруюцца з выкарыстаннем газавай хроматаграфіі, і пасля падтварджэння, што мэтавая чыстасць дасягнутая, збор працэсу завершаецца ў абодвух фазах. (Больш працэсных маршрутаў можна тачна дапрацаваць па розным матэрыялах для абаработкі.)

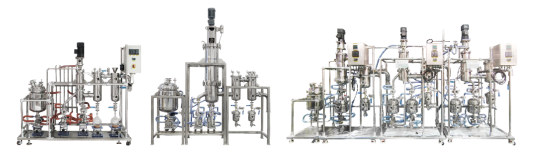

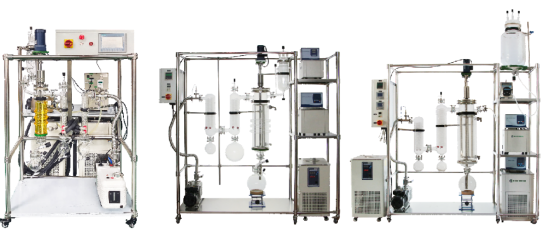

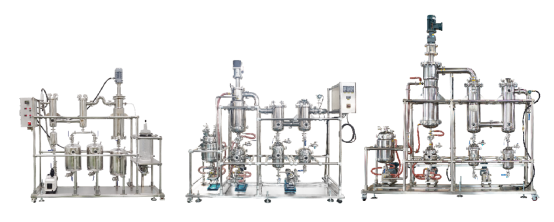

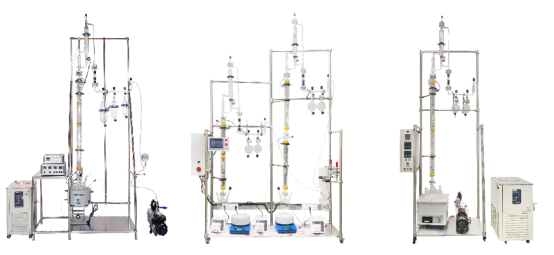

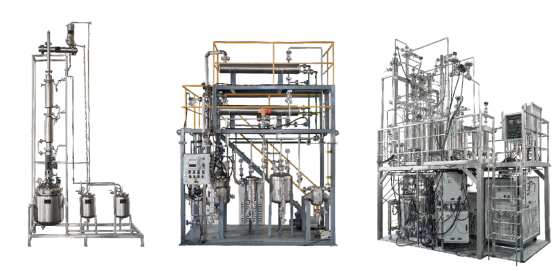

Асноўнае прыладдзе для працэсу:

YHCHEM Сістэма молекулярнай дыстыляцыі

Уключает у сябе тэла эвапарацыі з ўнутранай канденсацыйнай структурай, бак вадавання і пачатковага нагрэвання, апарат перадачы матэрыялу, вакуумную установку, юніт кантролю температуры, прыладу непарыўнага адпуску і іншыя. Молекулярная дыстыляцыя — гэта спецыяльная тэхналогія высокаага вакуумнага аддзелення, якая аддзеляе растынкі ў температурных ўмовах, якія значна меншыя за іх кипенні, пад экстра-высокім вакуумам, на аснове розніцы ў середнім свабодным шляху молекул у фазе газу. Гэта чымусь падыходзіць для чысценькасці тэплачутлівых і лёгка аксыдыруемых рэчывін, такіх як глыбіннае рыбае масяца. Падчас вытвору, YHCHEM сістэма молекулярнай дыстыляцыі можа аддзяляць кампаненты на аснове даўжыні і насыщенасці углерадных ланцоў жырных кислот у рыбацкім масяце ў высокаага вакуумнага ўмоў.

Перавагі:

Значна зніжае кіпенні матэрыялаў.

Высокае эфектыўнасць эвапарацыі.

Короткае час нагрэвання матэрыялаў.

Прамаль нізкае спадание ціскі.

Мадульны дызайн.

Інтэграваны кантроль.

YHCHEM Эвапарацыя цінкім слоем Сістэма

Уclude ўключает у сябе апарат для эвапарацыі цінкім слоем, танк прыгартавання і зберагання падачы, аддзел перадачы матэрыялаў, вакуумную апаратуру, апарат кантролю температуры, раз’ядку пар-жыдкасці, конденсатар, прыладу непарыўнай выліву і інш. Праз персаналізаваную дызайн-кампанію на аснове розных параметраў продукту нефты (такіх як колькасць падачы, швидодаў падачы, температура падачы і ўмоваў склада падачы), у умовах высоце вакуумнай среды, YHCHEM апарат для эвапарацыі цінкім слоем можа эфектна завяршыць патрабаванні па папярэднім аддзеленні складнікаў нефты ў ніжчых температурах.

Перавагі:

Непарыўны і стаялы спосаб падачы.

Матэрыялы з вышэйшым кипеннем могуся рэалізаваць ніжчуе кіпенне ў высоце вакуумнай среды.

Короткае часовая прысутнасць падчас перадачы тэплам, падыходзіць для тэплачулівых матэрыялаў.

Высокая эфектыўнасць эвапарацыі, добры апрадак аддзелу.

Швидкая шынтэнцыя працэсу, можа быць падключана да дыстыляцыйнай коланы для паднешэння чыстата продуктаў.

Кампактнае абсталяванне, маленькі заняты плошча.

YHCHEM дыстыляцыйная башня

Калонка дыстыляцыі Yuanhuai ўключае галоўны корпус калонкі, апаратуру кантролю температуры і ціскі, конденсацыйныя прылады, сістэмы кантролю коефіцыента рэфлуксу, прыклады для збору вынікаў і т.д. Yuanhuai стварае індывідуальныя падходы для розных матэрыялаў на аснове іх фізічных ўласцівасцей з дапамогай прафесійных сімуліраванняў, што дазваляе задавальняць вялікія патрабаванні да аддзелення мэтавых продуктаў.

Перавагі:

Вышэйшая тэарэтычная колькасць пластоў у поріўненні з звычайным абсталяваннем для дыстыляцыі, што прыводзіць да вышэйшай чыстоты продукта;

Модульны дызайн, сумясны з прыладамі, такімі як тонкафэнная дыстыляцыя;

Працуе ў высоцкаабсцісных умовах, дасягаючы ніжэйшую тэмпературу дыстыляцыйнага аддзелення;

Здатны выконваць як партыяльную, так і непарыўную дыстыляцыю;

З кантрольнай сістэмай Yuanhuai, якая дасягае таячнага кантролю ключавых параметраў, таких як температура, ціск, коефіцыент рэфлуксу, а таксама ўвод і вывад матэрыялаў.