YHCHEM uses a Reciprocating-Plate Extraction Column to extract phosphoric acid. Background: Phosphoric acid is a medium-strong triprotic acid that ionizes in three steps, is non-volatile, stable, and virtually non-oxidative. It has all the common p...

Share

YHCHEM uses a Reciprocating-Plate Extraction Column to extract phosphoric acid.

Background:

Phosphoric acid is a medium-strong triprotic acid that ionizes in three steps, is non-volatile, stable, and virtually non-oxidative. It has all the common properties of an acid. Pure phosphoric acid forms colorless orthorhombic crystals and becomes a viscous liquid. Phosphoric acid is miscible with water in any proportion.

Industrially, phosphoric acid is commonly produced by the wet process, where concentrated sulfuric acid reacts with calcium phosphate or phosphate rock, followed by the filtration to remove the slightly water-soluble calcium sulfate precipitate, resulting in a phosphoric acid solution. Phosphoric acid is an important chemical intermediate and can be used to produce many significant products.

In the fertilizer industry, it is used to make ammonium phosphate, triple superphosphate, superphosphate, and precipitated phosphate fertilizers.

In the inorganic chemical industry, it is used for the production of acid manganese phosphate, dipotassium hydrogen phosphate, disodium phosphate, potassium pyrophosphate, and various phosphates. Refined phosphoric acid is used to produce feed-grade calcium hydrogen phosphate.

In the pharmaceutical industry, it is used to make sodium glycerophosphate, iron phosphate, zinc phosphate, and as a pH adjuster for penicillin.

In the food industry, it is used to produce calcium glycerophosphate and as an acidic flavoring agent.

In the paint industry, it is used to produce metal anti-rust paint and flame retardant paint.

In the daily chemical industry, it is used as a detergent booster.

In the plastics and organic synthesis industry, it is used as a catalyst.

In the printing and dyeing industry, it is used as a chemical fire retardant finishing agent.

In the light industry, electromechanical, and instrumentation industries, it is used for phosphating solutions to treat the surface of metal parts.

Additionally, it is used as a latex coagulant, safety match soaking agent, pH adjuster, aluminum electroplating anti-rust agent, and in the preparation of plating solutions and pigments.

Aqueous Phase Phosphoric Acid Extraction Process and Core Equipment:

Wet phosphoric acid filtrate → Filtration and concentration → Reciprocating plate extraction tower TBP extraction → Extract phase concentration

Core equipment:

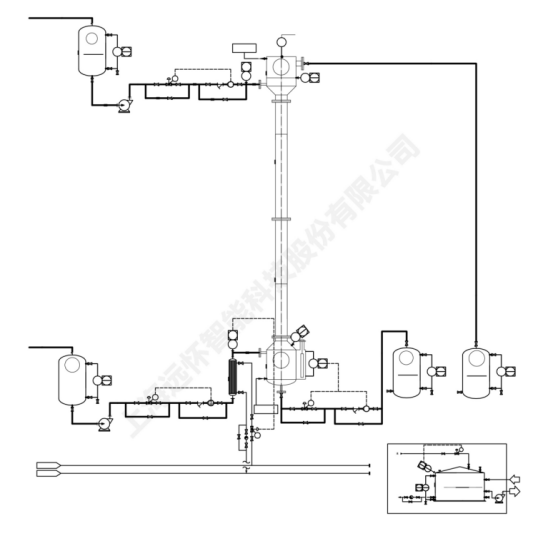

Reciprocating Screen Plate Extraction System Includes the Reciprocating-Plate Extraction Column (RPEC), extractant feed pre-heating exchanger, material storage tank, extractant storage tank, extract liquid storage tank, waste liquid storage tank, and automatic controller, etc.

The fundamental structure of the RPEC is a series of perforated plates installed on a central shaft, which is moved reciprocally by a drive mechanism at the top of the column. The light and heavy phases enter from the bottom and top of the tower, respectively. The reciprocating motion of the plates causes the counter-current contact of the two phases to be uniformly dispersed, providing a large mass transfer area, after which the light and heavy phases are clarified and separated at the top and bottom of the tower, completing the continuous counter-current extraction process.

Compared to other types of extractors, the RPEC is a high-efficiency continuous extraction equipment with external energy added, used for liquid-liquid extraction processes, with maximum volumetric efficiency, low solvent usage, saving solvent, reducing costs, and suitable for easily emulsified or impure materials. The tower is highly adjustable, making operations flexible and convenient, and widely applicable.

Process Automation Control:

Advanced and reliable.An advanced control system combined with the best detection methods ensures real and reliable detection of temperature, pressure, flow rate, and liquid level during the production process.

Simple operation.Clear and reasonable pipeline layout combined with systematic training enables operators to fully master the process operation in a short period of time.

Safety of the process.Multiple detectors combined with integrated control, using PLC and human-machine interface for control, centrally controlling multiple adjustable parameters such as feed and discharge flow rates and temperature.

Modular design.Through modular design, it can be directly used for the continuation of front-end processes. After the design is completed, it can also be adjusted according to different production situations, by adding or vacating some equipment based on the already designed complete set, realizing efficient utilization of energy and labor, and providing expandability of the process.