Waste lubricating oil is usually extracted from crude oil. Its components are mainly base oil and some additives. During use, it will deteriorate due to oxidation, impurities, etc., resulting in changes in physical or chemical properties, such as den...

Share

Waste lubricating oil is usually extracted from crude oil. Its components are mainly base oil and some additives. During use, it will deteriorate due to oxidation, impurities, etc., resulting in changes in physical or chemical properties, such as density, viscosity, flash point and other performance degradation and the generation of impurities such as organic acid salts, which makes it unable to meet the use standards and causes waste of resources. The process of removing the deteriorated components in the lubricating oil by physical or chemical methods to make it meet the use standards again is the regeneration of waste lubricating oil.

Common treatment methods

1.Physical Refining

The physical refining methods include centrifugal sedimentation, acid soil process, etc., which are mainly used to treat waste lubricating oil with low pollution and easy to remove pollutants. However, this method only has simple physical separation, impurities are not completely removed, and the refining effect is poor.

2.Chemical Refining

The chemical refining method mainly uses acid to react with impurities in waste lubricating oil for treatment. Wastewater and waste gas are easily generated in the process, which pollutes the environment and corrodes the equipment.

YHCHEM SOLUTION

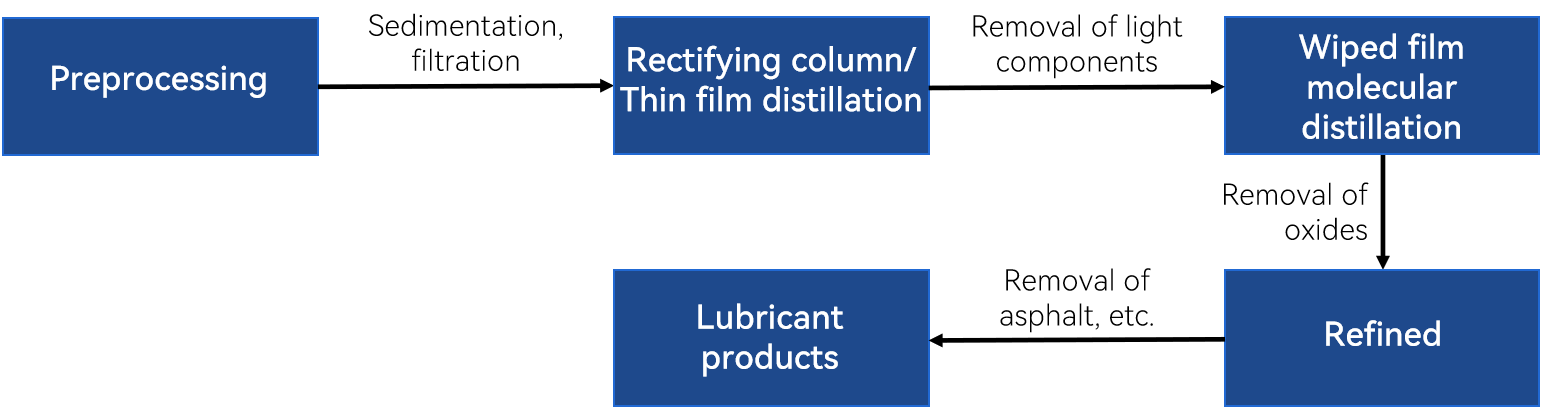

YHCHEM’s technical team can provide you with a complete set of processing systems based on distillation towers, thin film distillation or molecular distillation, with good refining effect and low solvent loss. It not only solves the problem of incomplete impurity removal in traditional physical refining methods, but also avoids the generation of pollutants and ensures the service life of the equipment.